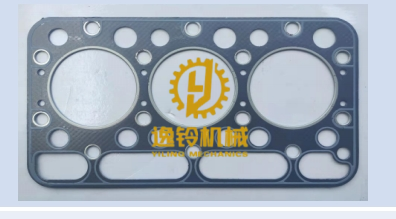

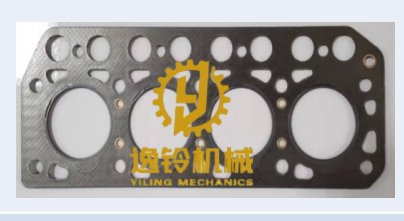

Head Gasket, HG-K4A MM408-466, MM408-454

Support Alibaba online purchase

Premium Head Gasket - HG-K4A MM408-466 / MM408-454

Ensure optimal engine performance and reliability with our high-quality Head Gasket designed for specific applications.

Product Overview

This Head Gasket (Part Numbers HG-K4A, MM408-466, MM408-454) is a critical sealing component for the engine combustion chamber, preventing the leakage of combustion gases, coolant, and engine oil. Manufactured to stringent standards, it provides a reliable seal under high pressure and temperature conditions, crucial for maintaining engine compression and preventing fluid intermixing.

Product Specifications

While specific dimensions may vary slightly between MM408-466 and MM408-454 variants to perfectly match the engine block and cylinder head configuration, the general specifications and material quality are consistent. Key parameters include:

Material Type: Often constructed from multi-layer steel (MLS), composite, or a combination for durability and sealing integrity.

Thickness: Precision engineered to ensure correct compression ratio upon installation.

Layer Configuration (for MLS): Specific number and design of layers for optimal stress distribution and sealing.

Gasket Design: Matches the exact port layout and bolt pattern of the compatible engine models (K4A, MM408 series).

Temperature Resistance: Designed to withstand extreme engine operating temperatures.

Pressure Resistance: Built to seal effectively against high combustion pressures.

Advantages and Selling Points

Superior Sealing: Provides a robust and long-lasting seal against combustion pressure, coolant, and oil leaks.

Durable Construction: Made from high-quality materials resistant to heat, pressure, and chemical degradation.

Precise Fitment: Engineered to exact OEM specifications for a perfect match with compatible engines.

Restores Compression: Proper sealing ensures maximum engine compression for efficient power delivery.

Prevents Engine Damage: Avoids costly damage caused by fluid leaks or overheating due to compromised sealing.

Reliable Performance: Contributes to stable engine operation and extended service life.

Applicable Equipment

This Head Gasket is specifically designed for engines belonging to the K4A and MM408 series. These engines are typically found in various types of compact and light-duty machinery.

Application Scenarios & Case Analysis

Engines compatible with this head gasket are commonly used in applications requiring reliable, compact power. These include:

Small Generators: Providing power for residential backup, small businesses, or portable power needs.

Case Example: A K4A-powered generator used on a construction site for power tools. A failing head gasket led to coolant loss and overheating. Replacing it with this specific HG-K4A gasket restored the cooling system integrity and allowed the generator to operate reliably under continuous load.Compact Construction Equipment: Such as mini-excavators, skid steer loaders, and compact track loaders.

Case Example: An MM408-equipped mini-excavator experienced reduced power and white smoke from the exhaust, indicating a breach between the combustion chamber and coolant passage. Installing the correct MM408 head gasket resolved the issue, restoring engine performance and preventing further damage.Agricultural Machinery: Smaller tractors, tillers, and specialized harvesting equipment.

Case Example: A farmer's K4A engine in a small tractor developed an oil leak external to the engine block, traced back to the head gasket seam. Replacing the gasket sealed the leak, ensuring the engine maintained proper oil levels and preventing potential lubrication issues during demanding fieldwork.Other Industrial Applications: Pumps, compressors, and material handling equipment.

Case Example: An MM408 engine powering a hydraulic pump in a small factory setting showed signs of cross-contamination between oil and coolant. A new head gasket corrected the internal seal failure, ensuring the longevity and proper function of both the engine and the hydraulic system.

Related and Similar Products

Customers needing a head gasket for K4A/MM408 engines might also require or be interested in related engine components, such as:

Valve Cover Gaskets: Seals the valve cover to prevent oil leaks (Applicable to K4A, MM408, and many other engines).

Intake and Exhaust Manifold Gaskets: Seals manifolds to the cylinder head for proper air intake and exhaust flow (Applicable to K4A, MM408, and most internal combustion engines).

Oil Pan Gaskets: Seals the oil pan to the engine block (Applicable to K4A, MM408, and most engines with an oil pan).

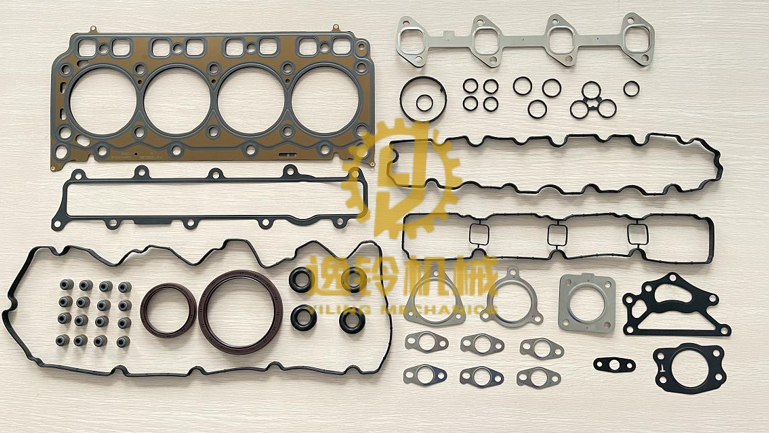

Full Engine Gasket Kits: Comprehensive kits containing all necessary gaskets and seals for a complete engine overhaul (Available for K4A, MM408, and various other engine models).

Piston Rings, Bearings, Seals: Internal engine components often replaced during major repairs involving the head gasket (Applicable widely across engine types).

Common Installation & Maintenance Issues and Solutions

Proper installation and maintenance are crucial for head gasket longevity. Common issues include:

Issue: Coolant or Oil Leaks (external).

Cause: Improper torqueing sequence or values, warped cylinder head/block surface, damaged gasket during installation.

Solution: Always follow the manufacturer's specified torque sequence and values. Ensure cylinder head and block surfaces are perfectly clean and flat before installation. Handle the gasket carefully.Issue: Overheating.

Cause: Gasket failure allowing combustion gases into the cooling system, restricting coolant flow, or coolant leakage.

Solution: Replace the head gasket. Thoroughly flush the cooling system. Check for other causes of overheating (thermostat, radiator, water pump).Issue: White Smoke from Exhaust.

Cause: Coolant leaking into the combustion chamber due to gasket failure.

Solution: Replace the head gasket. Check for potential cylinder head cracks (though less common).Issue: Reduced Compression/Engine Misfire.

Cause: Gasket failure between adjacent cylinders or between a cylinder and a fluid passage.

Solution: Replace the head gasket. Perform a compression test to confirm sealing in all cylinders after replacement.General Maintenance Tip: Regularly check coolant and oil levels. Address any signs of leaks or overheating promptly. Use the correct type and quality of coolant and oil recommended by the engine manufacturer.