CYLINDER HEAD GASKET SET OVERHAUL KIT for KOMATSU 6D140 6D140-N DIESEL ENGINE PARTS 6210-17-1814 6218-K1-9901 6218-K2-9901

Support Alibaba online purchase

Premium Cylinder Head Gasket Set Overhaul Kit for Komatsu 6D140 / 6D140-N Diesel Engines

Product Overview

Ensure the optimal performance and longevity of your Komatsu 6D140 and 6D140-N diesel engines with our high-quality Cylinder Head Gasket Set Overhaul Kit. This comprehensive kit provides all the essential gaskets and seals required for a complete cylinder head overhaul, preventing leaks and maintaining proper engine compression. Manufactured to meet or exceed OEM specifications, our kit guarantees a precise fit and reliable sealing, extending the service life of your valuable equipment.

This kit is an indispensable part for routine maintenance and major repairs, designed to restore your engine's efficiency and power. Trust in our durable components to keep your Komatsu machinery operating at peak performance in demanding environments.

Product Specifications

Part Number (Cylinder Head Gasket): 6210-17-1814

Part Number (Overhaul Kit 1): 6218-K1-9901

Part Number (Overhaul Kit 2): 6218-K2-9901

Engine Compatibility: Komatsu 6D140, Komatsu 6D140-N Diesel Engines

Kit Contents: Comprehensive set including cylinder head gasket, valve stem seals, manifold gaskets, oil seals, and other necessary components for a complete overhaul. (Exact contents may vary slightly based on specific kit version).

Material: High-grade, durable materials resistant to high temperatures, pressure, and chemical corrosion.

Manufacturing Standards: Produced to OEM or higher standards for optimal performance and reliability.

Key Advantages & Selling Points

Superior Sealing: Precisely engineered gaskets ensure an airtight and leak-free seal, maintaining optimal compression and preventing fluid loss.

Enhanced Durability: Constructed from premium materials, designed to withstand the harsh operating conditions of heavy-duty diesel engines, extending engine life.

OEM Quality & Fit: Manufactured to meet or exceed original equipment manufacturer specifications, guaranteeing a perfect fit and reliable performance.

Comprehensive Kit: Includes all necessary components for a complete cylinder head overhaul, saving time and simplifying the repair process.

Cost-Effective Solution: A reliable replacement kit that helps avoid costly engine damage and reduces downtime, offering excellent value for money.

Restored Engine Performance: Helps to restore engine power, fuel efficiency, and reduce emissions by ensuring proper combustion and preventing internal leaks.

Applicable Equipment and Application Scenarios

This Cylinder Head Gasket Set Overhaul Kit is specifically designed for Komatsu equipment powered by the Komatsu 6D140 and 6D140-N diesel engines. These robust engines are widely used in a variety of heavy-duty machinery known for their reliability and performance in challenging environments.

Applicable Equipment:

Komatsu Excavators: Often found in models requiring significant digging and lifting power.

Komatsu Wheel Loaders: Used for material handling, loading trucks, and general earthmoving.

Komatsu Dozers: Employed in land clearing, grading, and pushing large quantities of material.

Komatsu Graders: Essential for road construction and maintenance, creating flat surfaces.

Komatsu Dump Trucks: Heavy-duty haulage in mining and construction sites.

And other Komatsu heavy machinery equipped with the 6D140 / 6D140-N engine.

Application Scenarios & Case Analysis:

Construction Sites: Komatsu excavators (e.g., PC300-6, PC400-6 series) powered by 6D140 engines are workhorses in large-scale construction projects. A failing cylinder head gasket can lead to coolant leaks, overheating, and loss of engine power, causing significant project delays. Our overhaul kit ensures these critical machines can maintain their operational tempo for trenching, foundation work, and demolition.

Mining Operations: Komatsu wheel loaders (e.g., WA450-3, WA500-3) are vital for loading ore and overburden in open-pit mines. The extreme conditions, dust, and continuous operation demand robust engine components. A worn gasket can result in decreased engine efficiency and increased fuel consumption, directly impacting productivity and operational costs. Replacing with our quality kit extends the life of these machines in a highly demanding environment.

Road Building and Infrastructure Projects: Komatsu dozers (e.g., D155A-5) and graders are fundamental for preparing ground and creating stable surfaces. Engine overheating due to gasket failure can lead to critical component damage and unplanned downtime, jeopardizing project timelines. Our kit facilitates efficient repairs, ensuring these machines continue to lay the groundwork for new roads and essential infrastructure.

Quarrying and Aggregate Production: Dump trucks and loaders are under constant stress moving heavy loads of stone and gravel. A complete cylinder head gasket overhaul is crucial for engines experiencing wear from high operating hours, preventing costly breakdowns and maintaining the continuous flow of materials from quarry to processing plants.

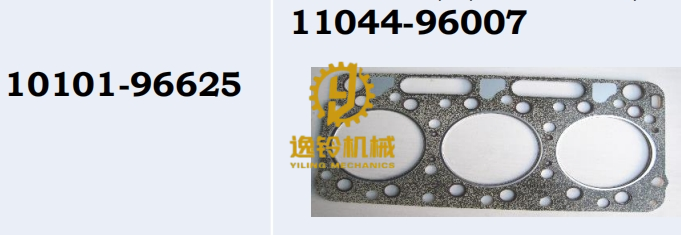

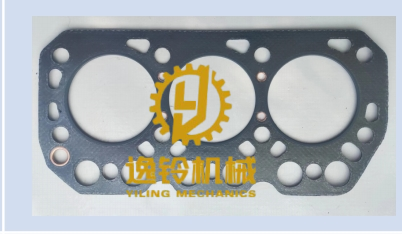

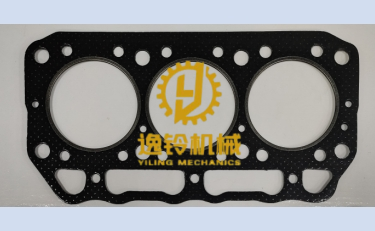

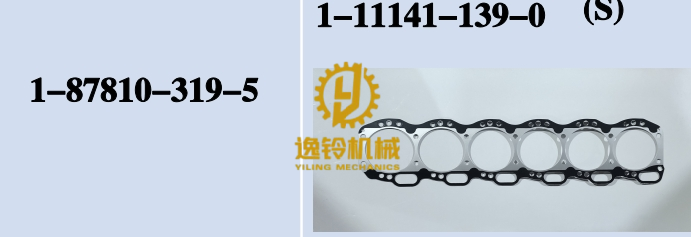

Related & Similar Products

We offer a comprehensive range of genuine and aftermarket diesel engine parts to meet various Komatsu maintenance and repair needs. While this product focuses on the 6D140/6D140-N engines, we also supply components for other popular Komatsu engine models.

Complete Engine Overhaul Kits for Komatsu S6D125:

Applicable Equipment: Komatsu PC400-7 excavators, Komatsu WA470 wheel loaders, and other machinery utilizing the S6D125 engine, common in larger excavators and loaders.

Fuel Injector Assemblies for Komatsu 6D95:

Applicable Equipment: Komatsu PC200-7 excavators, Komatsu GD511A graders, and other mid-range Komatsu construction equipment.

Water Pumps & Oil Coolers for Komatsu SA6D170:

Applicable Equipment: Komatsu HD785 dump trucks, Komatsu D375A dozers, used in heavy-duty mining and large earthmoving applications.

Crankshafts and Con Rods for Komatsu 4D102:

Applicable Equipment: Smaller Komatsu excavators (e.g., PC200-6), forklifts, and light construction machinery.

Installation & Maintenance: Common Issues and Solutions

Proper installation and regular maintenance are crucial for the longevity and performance of your cylinder head gasket set. Here are some common issues and their solutions:

Common Issues:

Coolant Leaks: Visible coolant seepage around the cylinder head, typically indicating a failing head gasket or improper installation.

Oil Leaks: Oil appearing around the cylinder head or exhaust manifold, often due to degraded gasket material or incorrect torque.

Overheating: Engine temperature rising rapidly, often a symptom of combustion gases leaking into the coolant system or coolant loss from a failed gasket.

Loss of Compression / White Smoke: If exhaust emits white smoke, it suggests coolant is burning in the combustion chamber due to a compromised head gasket. Loss of engine power can also occur.

Rough Idling / Misfires: Combustion gases leaking between cylinders can cause uneven engine operation.

Solutions & Best Practices:

Thorough Surface Preparation: Before installing a new gasket, ensure both the cylinder head and engine block surfaces are absolutely clean, flat, and free of any debris, corrosion, or old gasket material. Minor imperfections can lead to leaks.

Correct Torque Sequence & Specifications: Always follow the manufacturer's specified torque sequence and values for cylinder head bolts. Use a calibrated torque wrench. Incorrect tightening can lead to uneven pressure, warping, and premature gasket failure.

New Head Bolts (Recommended): For many modern diesel engines, it's recommended to replace cylinder head bolts during an overhaul, as they can stretch over time and lose their clamping force.

Proper Coolant System Maintenance: Regularly flush and refill the coolant system with the correct type and mixture of coolant. Contaminated or improper coolant can accelerate gasket degradation.

Check for Warped Components: After a head gasket failure, particularly due to overheating, it is critical to check the cylinder head and engine block for warping or cracks. Machining (skimming) the cylinder head might be necessary to ensure a perfectly flat sealing surface.

Professional Installation: Due to the precision required, it is highly recommended that cylinder head gasket replacement and engine overhauls be performed by certified technicians.