Wholesale Construction Machinery Part Cheap Sale Spare Parts Forklift 6D170-1 Engine Overhaul Gasket Kit for komatsu

Support Alibaba online purchase

Precision Engine Overhaul: Komatsu 6D170-1 Gasket Kit

Product Overview

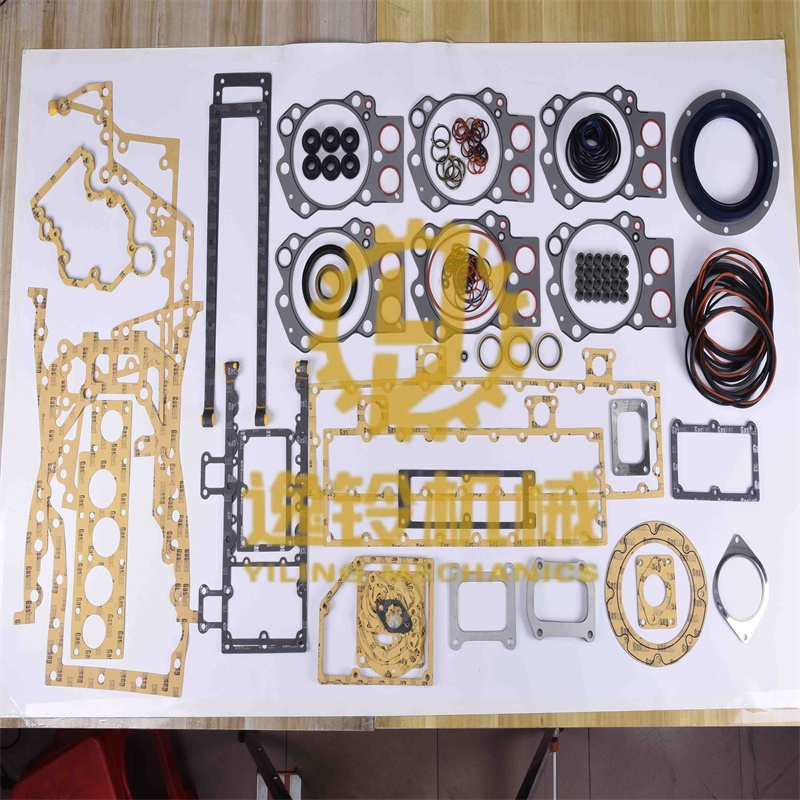

Introducing our high-quality Wholesale Construction Machinery Part Cheap Sale Spare Parts Forklift 6D170-1 Engine Overhaul Gasket Kit, specifically engineered for Komatsu engines. This comprehensive gasket kit is essential for thorough engine overhauls, ensuring optimal sealing and performance for your heavy machinery. Designed to meet or exceed OEM specifications, our gasket kit provides a reliable and durable solution for maintaining the integrity and efficiency of your Komatsu 6D170-1, S6D170, and S6D170-1C diesel engines.

Product Parameters

Engine Model Compatibility: Komatsu 6D170-1, S6D170, S6D170-1C

Type: Engine Overhaul Gasket Kit (Full Gasket Set / Top Repair Kit)

Material: High-grade Metal and durable sealing compounds

Original Number (Reference): 6162-K1-5000 (May vary based on specific components)

Condition: New

Engine Type: Diesel

Application Area: Construction, Industry, Agriculture, Genset, Marine, Material Handling

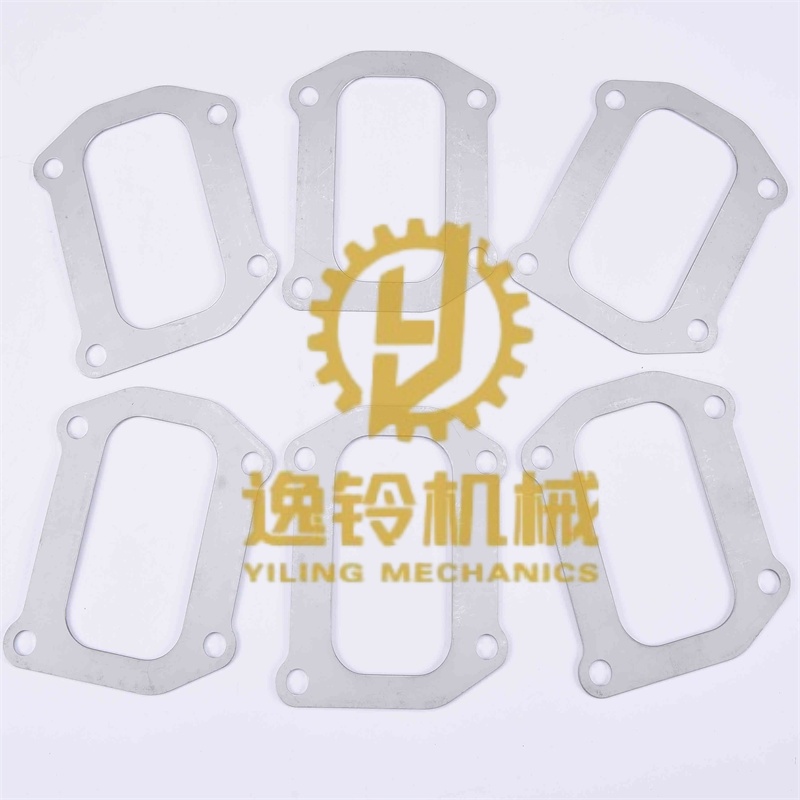

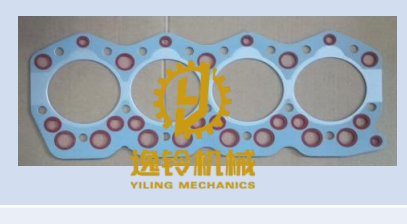

Key Components Included: Head Gasket, Crankshaft Oil Seals (Front & Rear), Valve Stem Oil Seals, Oil Pan Gasket Set, Valve Cover Gasket, Exhaust Manifold Gasket, Intake Manifold Gasket, Water Pump Gasket, Copper Washer Gasket Set, Timing Cover Gasket, Engine Rubber Set, and other essential gasket sets.

Warranty: Typically 6 months (may vary by supplier and specific component)

Product Advantages & Selling Points

Superior Sealing Performance: Crafted from high-quality materials to provide excellent bolt stress retention properties and prevent leaks, ensuring maximum engine compression and efficiency.

Enhanced Durability: Engineered for longevity and robust performance under demanding operating conditions.

Ease of Installation: Features proprietary anti-stick coating for easy removal and precise fitment during assembly, simplifying the overhaul process.

Cost-Effective Solution: Offers a reliable aftermarket alternative to OEM parts without compromising on quality, contributing to significant savings on maintenance costs.

Comprehensive Kit: Includes all necessary gaskets and seals for a complete engine overhaul, ensuring all critical areas are properly sealed.

Applicable Equipment and Application Scenarios

This engine overhaul gasket kit is primarily designed for Komatsu 6D170-1, S6D170, and S6D170-1C diesel engines. These powerful engines are widely utilized across various heavy construction, mining, and industrial machinery, including but not limited to:

Excavators: Such as the Komatsu PC1000-1 and other large excavators used for digging, trenching, and material handling in construction sites and mining operations.

Mining Trucks: Heavy-duty trucks crucial for transporting vast quantities of ore and overburden in surface mining environments.

Wheel Loaders: Employed in construction, quarrying, and material handling for loading aggregate, soil, and other materials.

Dozers and Motor Graders: Essential for land clearing, grading, and site preparation in civil engineering and infrastructure projects.

Forklifts: Heavy-duty industrial forklifts used in large warehouses, ports, and construction sites for lifting and moving heavy loads.

Gensets (Generator Sets): Providing reliable power generation in remote areas or as backup power for industrial facilities.

Marine Applications: Used in certain marine vessels requiring robust diesel engines.

Case Study: Maximizing Uptime in Mining Operations

In large-scale surface mining, engine reliability is paramount. A failing head gasket in a Komatsu 6D170-1 engine can lead to significant downtime and costly repairs. By proactively using a high-quality overhaul gasket kit during scheduled maintenance, mining companies can prevent unexpected engine failures. For instance, early identification and replacement of worn gaskets have reportedly saved one operation up to US$250,000 in engine replacement and associated downtime costs. Regular engine overhauls with a complete gasket kit contribute to increased truck fuel system availability and overall operational efficiency, ensuring continuous production and reduced maintenance expenditures. This commitment to proper engine maintenance ensures that heavy equipment like large excavators and mining trucks can operate at peak performance, even in challenging environments.

Related Products

Beyond the 6D170-1 Engine Overhaul Gasket Kit, we also offer a wide range of related engine components and gasket sets for various Komatsu and other heavy machinery engines:

Gasket Sets for Other Komatsu Engine Models: Including 4D105, 6D95, 6D105, 6D140, NH220, NT855, and more. Applicable for various Komatsu excavators, bulldozers, wheel loaders, and graders.

Engine Components:

Cylinder Head & Block: Critical structural components for engine integrity.

Piston & Piston Rings: Essential for combustion and sealing within the cylinders.

Cylinder Liners: Provide the wear surface for pistons.

Crankshaft & Camshaft: Core components for engine rotation and valve timing.

Bearings (Main, Con Rod): Ensure smooth rotation of crankshaft and connecting rods.

Oil Pump & Water Pump: Maintain lubrication and cooling system circulation.

Valve Series Products: Intake and exhaust valves, valve guides, valve seats, and valve springs.

Fuel System Components: Fuel injectors, nozzles, and fuel lines.

Turbochargers & Starter Motors: Enhance engine power and facilitate engine starting.

Alternators: Generate electrical power for the machinery's systems.

These products are applicable to a broad spectrum of heavy equipment from various manufacturers, ensuring comprehensive support for your fleet's maintenance needs.

Installation & Maintenance: Common Issues and Solutions

Proper installation and regular maintenance are crucial for the longevity and performance of engine gasket kits. Here are some common issues encountered and their solutions:

Common Issues:

Gasket Leakage: Often caused by improper torqueing, warped mating surfaces, or using an incorrect gasket type.

Premature Wear: Can result from inadequate lubrication, overheating, or contaminants in the engine oil.

Engine Overheating: A damaged head gasket can lead to coolant mixing with oil or combustion gases entering the cooling system.

Reduced Engine Compression: Indicates poor sealing, leading to loss of power and fuel efficiency.

Difficulty in Gasket Removal: Old, stuck gaskets can make replacement challenging.

Solutions & Best Practices:

Proper Installation:

Preparation: Before starting, ensure the engine is cool, the battery is disconnected, and all necessary fluids are drained. Remove any obstructing components to gain clear access to the gasket.

Surface Cleaning: Thoroughly clean all mating surfaces (engine block, cylinder head) to remove old gasket material, debris, dirt, and coolant residue. Use a gasket scraper or appropriate tool carefully to avoid damaging surfaces. Inspect surfaces for any warping or damage that may require machining.

Correct Torqueing: Always follow the manufacturer's torque specifications and sequence when tightening bolts. Uneven or incorrect torque can lead to leaks and premature gasket failure.

Lubrication: Apply a thin layer of engine oil to new gaskets (if recommended by the manufacturer) to aid in seating and prevent tearing during installation.

Regular Maintenance:

Compression & Leakage Tests: Conduct these tests regularly to monitor cylinder health and detect any early signs of wear or damage to the cylinder liner, piston, or gaskets.

Periodic Inspections: Visually inspect engine components, including the cylinder liner, piston, piston rings, and cylinder head for signs of wear, corrosion, or damage.

Oil & Coolant Management: Ensure engine oil is filled to the required level and changed according to the maintenance schedule. Maintain proper coolant levels and temperature, and regularly flush the cooling system to prevent blockages.

System Checks: Verify that the air, fuel, and ignition systems are functioning correctly to prevent issues that can lead to excessive cylinder wear.

Troubleshooting Gasket Removal:

If an old gasket is stuck, gently tap around the perimeter with a soft hammer (rubber or plastic mallet) to loosen it. Avoid excessive force that could damage engine components.

Utilize specialized tools like gasket scrapers or liner pullers for stubborn components, ensuring they are used carefully to prevent damage to the engine block.