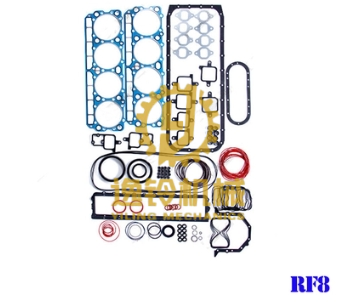

6D170-1 Gasket Repair Kit 6162-K2-5000 For Komatsu Engine Repair Parts Set

Support Alibaba online purchase

6D170-1 Gasket Repair Kit 6162-K2-5000 for Komatsu Engine Repair Parts Set

Ensure the longevity and optimal performance of your Komatsu engine with our premium 6D170-1 Gasket Repair Kit 6162-K2-5000. This comprehensive repair set is meticulously designed to meet the exact specifications of Komatsu engines, providing a reliable and durable solution for your maintenance and overhaul needs. Crafted from high-quality materials, this kit ensures a perfect seal, preventing leaks and maintaining consistent engine pressure for peak operational efficiency.

Product Specifications

Part Number: 6162-K2-5000

Engine Model Compatibility: Komatsu 6D170-1 series engines

Kit Contents: Includes all necessary gaskets, seals, and O-rings for a complete engine overhaul (specific contents may vary slightly based on manufacturing batch, but always comprehensive for the intended repair).

Material: High-grade, heat-resistant, and durable sealing materials, engineered for extreme engine conditions.

Quality Assurance: Manufactured to OEM standards for precise fit and superior performance.

Key Advantages & Selling Points

Precision Fit: Engineered to exact Komatsu specifications, guaranteeing a perfect seal and preventing costly leaks.

Durability: Made from robust, high-quality materials resistant to high temperatures, pressure, and corrosive fluids, ensuring a longer lifespan for your engine.

Comprehensive Solution: This complete kit provides all necessary components for a full gasket replacement, saving you time and hassle in sourcing individual parts.

Enhanced Engine Performance: Restores optimal compression and prevents oil/coolant mixing, leading to improved fuel efficiency and power output.

Cost-Effective: A proactive repair using a quality gasket kit can prevent more severe and expensive engine damage down the line.

Applicable Equipment

This 6D170-1 Gasket Repair Kit 6162-K2-5000 is specifically designed for Komatsu equipment powered by the Komatsu 6D170-1 series engine. This includes, but is not limited to:

Komatsu Excavators: PC1250-7, PC1250SP-7, PC1250LC-7, PC1600-1, PC1800-6

Komatsu Wheel Loaders: WA800-3, WA900-3

Komatsu Dozers: D375A-5, D475A-5

Komatsu Dump Trucks: HD785-5, HD785-7

Application Scenarios & Case Studies

The Komatsu 6D170-1 engine, and by extension the equipment it powers, is a workhorse in demanding industries. This gasket repair kit is crucial for maintaining these machines in various high-stress environments.

Mining Operations: Large excavators like the PC1250 series are fundamental in open-pit and underground mining for overburden removal and ore extraction. A failing gasket in such a critical machine can lead to significant downtime, impacting production targets. Regular maintenance with this gasket kit ensures these machines operate continuously under extreme dust, temperature, and load conditions.

Heavy Construction Projects: Komatsu wheel loaders (e.g., WA800-3) are indispensable for moving massive quantities of aggregates, sand, and other materials on large construction sites. Engine integrity is paramount for these machines, as they often run for extended hours. A timely gasket replacement prevents coolant leaks or oil contamination, which can lead to engine overheating and catastrophic failure.

Quarrying & Aggregate Production: Dozers like the D375A-5 are used for ripping and pushing material in quarries. These environments are notoriously tough on engines due to abrasive dust and constant heavy loads. Maintaining the engine's seal with a quality gasket kit is vital to prevent premature wear and ensure consistent power delivery for these high-demand tasks.

Large-Scale Infrastructure Development: Dump trucks such as the HD785-7 are the backbone of large infrastructure projects, transporting excavated earth, rock, and construction materials across vast distances. Engine reliability is non-negotiable for these vehicles. The 6D170-1 gasket kit provides the necessary components to overhaul the engine, ensuring these trucks can withstand continuous heavy hauls and long operating hours without unexpected breakdowns.

Related & Similar Products

In addition to the 6D170-1 Gasket Repair Kit, we offer a wide range of Komatsu engine repair parts to keep your machinery running smoothly. These include:

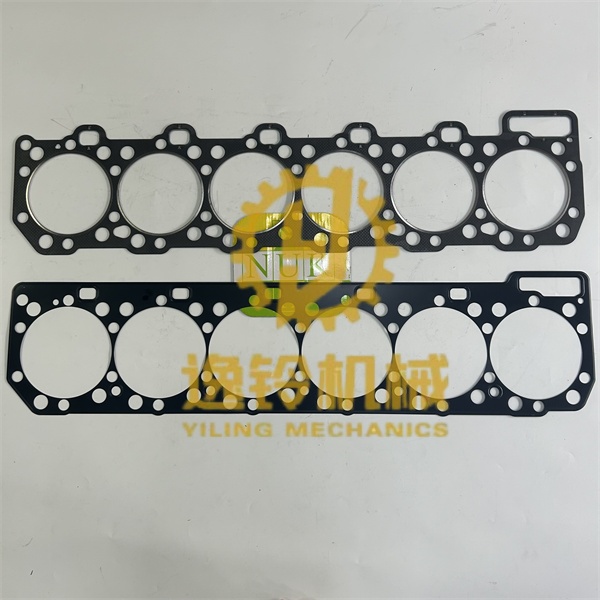

Cylinder Head Gasket Sets: For specific top-end engine repairs. Applicable to various Komatsu engine models, including PC200-8, PC300-7, and WA470-6.

Engine Overhaul Kits: More extensive kits for complete engine rebuilds, often including pistons, liners, bearings, and full gasket sets. Suitable for engines like the Komatsu SAA6D107E-1 and SAA6D125E-3, found in excavators like the PC360-7 and PC400-8.

Oil Pan Gaskets: Essential for preventing oil leaks from the bottom of the engine. Compatible with a broad range of Komatsu engines across different equipment types.

Valve Cover Gaskets: Prevents oil leaks from the top of the engine. Available for various Komatsu engine series.

Front and Rear Crankshaft Seals: Crucial for preventing oil leaks at the crankshaft ends. Applicable to almost all Komatsu engine models.

Common Installation & Maintenance Issues & Solutions

Proper installation and regular maintenance are crucial for the longevity of your gasket kit and engine. Here are some common issues and their solutions:

Issue: Gasket Leaks Post-Installation.

Solution: Often caused by improper surface preparation (residual old gasket material, dirt, or oil) or incorrect torque application. Always ensure mating surfaces are meticulously clean and flat. Follow the manufacturer's torque specifications and sequence precisely, typically in multiple stages. Retorque after initial run-in if recommended.Issue: Premature Gasket Failure/Blowout.

Solution: Can be due to engine overheating, incorrect gasket material for the application, or excessive engine vibrations. Diagnose the root cause of overheating (e.g., faulty thermostat, clogged radiator) and address it. Ensure you are using the correct gasket kit for your specific engine model. Check engine mounts for excessive vibration.Issue: Damaged Gasket During Handling/Installation.

Solution: Gaskets, especially head gaskets, can be delicate. Handle them with care, avoiding bending or creasing. Store them flat in their original packaging until ready for use. Use appropriate tools for installation to prevent accidental damage.Issue: Incompatible Sealing Compounds Used.

Solution: Some gaskets require specific sealants, while others are designed to be installed dry. Always refer to the Komatsu service manual for the correct procedure. Using the wrong sealant or too much can lead to squeeze-out that clogs oil passages or creates an improper seal.Issue: Coolant or Oil Contamination.

Solution: After a major gasket replacement, especially a head gasket, it's crucial to thoroughly flush the cooling system and change the engine oil to remove any contaminants that might have entered during the repair or due to the previous gasket failure.