6D170 Overhaul Rebuild Kit fits for Komatsu Engine 6D170

Support Alibaba online purchase

6D170 Overhaul Rebuild Kit for Komatsu Engines

Product Overview

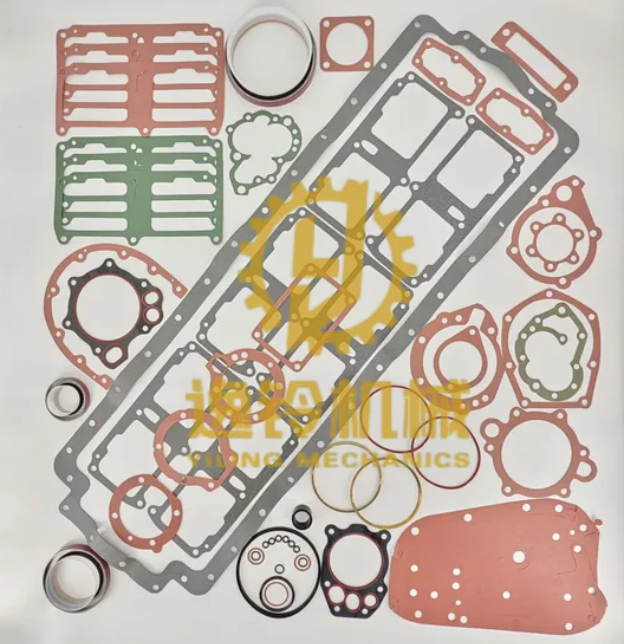

Ensure the longevity and optimal performance of your Komatsu heavy machinery with our premium 6D170 Overhaul Rebuild Kit. Specifically engineered for Komatsu 6D170 engines, this comprehensive kit provides all the essential components needed for a full engine overhaul, restoring your equipment to its original power and efficiency. Designed with precision and manufactured from high-quality materials, our rebuild kit guarantees reliability and durability, minimizing downtime and maximizing productivity.

Product Parameters

Engine Model Compatibility: Komatsu 6D170 Series Engines

Kit Type: Full Engine Overhaul Rebuild Kit

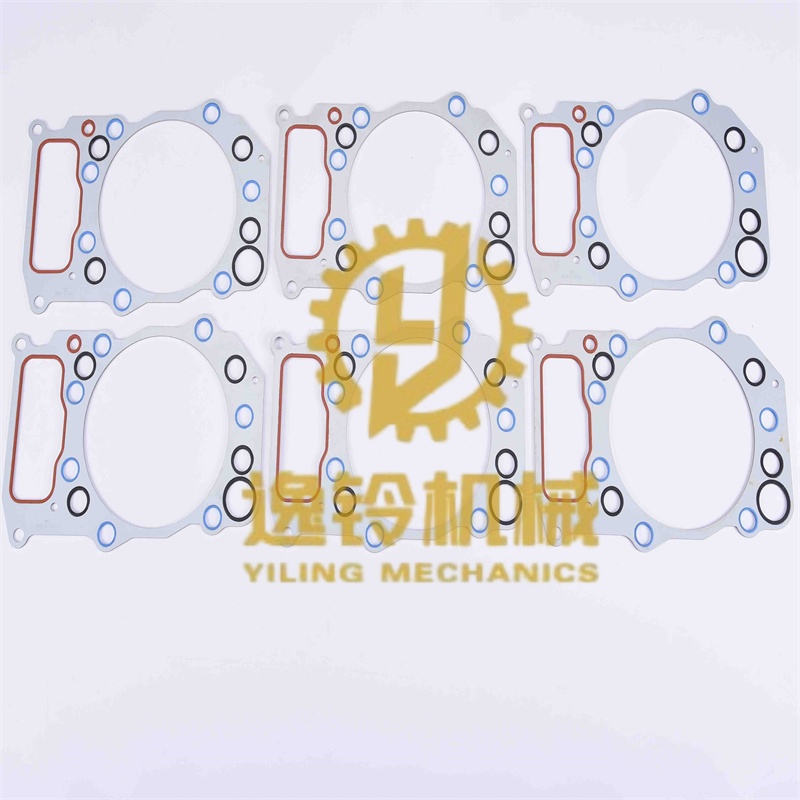

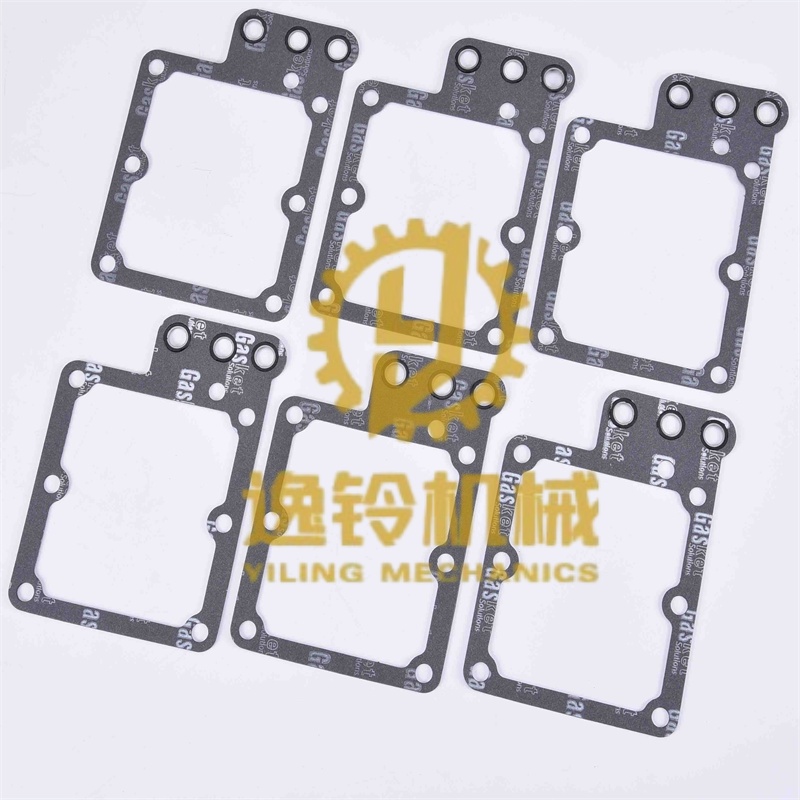

Components Included: Pistons, Piston Rings, Cylinder Liners, Main Bearings, Con Rod Bearings, Thrust Washers, Gasket Kit (Full Set), Valve Guides, Valve Seats, Oil Seals, etc. (Specific contents may vary slightly by kit version)

Material Quality: OEM equivalent or superior materials for enhanced durability and performance.

Precision Fit: Engineered for exact fitment, ensuring seamless installation and optimal engine function.

Key Advantages & Selling Points

Comprehensive Solution: All-in-one kit eliminates the need for sourcing individual parts, saving time and effort.

Enhanced Engine Lifespan: Restores engine to near-new condition, significantly extending operational life.

Optimized Performance: Improves fuel efficiency, reduces oil consumption, and restores horsepower.

Reduced Downtime: High-quality components ensure reliable repairs, minimizing future breakdowns.

Cost-Effective: A more economical alternative to engine replacement, offering significant savings.

Guaranteed Quality: Manufactured to strict quality control standards for peace of mind.

Applicable Equipment

This 6D170 Overhaul Rebuild Kit is perfectly suited for a wide range of Komatsu heavy equipment powered by the 6D170 engine, including but not limited to:

Komatsu Excavators: PC600, PC650, PC750, PC800 series and similar models.

Komatsu Wheel Loaders: WA600, WA700 series and similar models.

Komatsu Dozers: D375, D475 series and similar models.

Komatsu Off-Highway Trucks: HD series (e.g., HD465, HD605) and similar models.

Other Komatsu Construction and Mining Machinery: Any equipment utilizing the Komatsu 6D170 engine.

Application Scenarios & Case Studies

The Komatsu 6D170 engine, and thus the equipment it powers, operates in some of the most demanding environments globally. Our rebuild kit is crucial for maintaining performance in these critical applications:

Mining Operations:

In large-scale open-pit and underground mining, Komatsu excavators and haul trucks equipped with 6D170 engines are continuously moving massive amounts of earth and ore. The high stress and prolonged operating hours in dusty and abrasive conditions lead to inevitable engine wear. An overhaul using our 6D170 kit restores lost power, reduces excessive oil consumption, and ensures the machinery can withstand the rigorous demands of 24/7 mining cycles.

Case Study: A major iron ore mine in Australia experienced significant power loss and increased fuel consumption in their Komatsu PC800 excavators. After installing our 6D170 Overhaul Rebuild Kits, the excavators regained full digging force, reduced fuel consumption by 15%, and extended their service interval, leading to a substantial increase in material moved per shift.

Large-Scale Construction Projects:

From dam construction to infrastructure development and commercial building sites, Komatsu dozers and wheel loaders are essential for earthmoving, grading, and material handling. These machines often work on uneven terrain, under heavy loads, and sometimes in extreme temperatures. Engine overhauls are vital to maintain the necessary torque and reliability.

Case Study: During a major highway expansion project in North America, a fleet of Komatsu WA600 wheel loaders began showing signs of engine fatigue after thousands of hours. Implementing our 6D170 kits during scheduled maintenance periods allowed these machines to return to peak efficiency, significantly improving loading cycles and ensuring project deadlines were met without costly equipment replacement.

Quarrying & Aggregate Production:

Komatsu machinery in quarries faces harsh conditions with constant exposure to dust and vibrations from crushing and screening operations. The 6D170 engine powers crucial equipment like large excavators used for breaking and loading rock. Regular engine overhauls are preventative measures against catastrophic failures and maintain high production rates.

Case Study: A quarry operator in Europe noticed a decrease in hydraulic response and longer cycle times from their Komatsu PC750 excavators. A diagnostic revealed engine wear. After using our 6D170 Overhaul Rebuild Kits, the excavators' hydraulic power was fully restored, leading to a 10% increase in daily aggregate output and a dramatic reduction in unscheduled maintenance.

Related & Similar Products

Beyond the 6D170, we offer a wide range of overhaul rebuild kits for other Komatsu engine models, ensuring you can find the right solution for various equipment types:

Komatsu SAA6D125E Overhaul Kit: Suitable for Komatsu excavators (e.g., PC400, PC450), wheel loaders (e.g., WA470), and dozers (e.g., D155) commonly found in large construction and mining.

Komatsu SAA6D140E Overhaul Kit: For larger Komatsu excavators (e.g., PC800, PC1250) and off-highway trucks (e.g., HD325), primarily used in heavy mining and quarrying.

Komatsu SAA12V140E Overhaul Kit: Designed for the largest Komatsu mining shovels (e.g., PC3000, PC4000) and haul trucks (e.g., HD785), operating in extreme, high-production mining environments.

Komatsu 4D95/6D102/6D107 Overhaul Kits: Covering a broader range of smaller to medium-sized Komatsu excavators (e.g., PC200, PC220), bulldozers (e.g., D65), and compact equipment used in general construction and civil engineering.

Each of these kits is designed with the same commitment to quality and precision as our 6D170 kit, ensuring reliable performance across the entire Komatsu fleet.

Common Installation & Maintenance Issues and Solutions

While our 6D170 Overhaul Rebuild Kit is designed for straightforward installation, some common issues can arise during the process and ongoing maintenance. Here are a few and their solutions:

1. Improper Component Cleaning:

Issue: Residual dirt, old gasket material, or carbon deposits left on mating surfaces or within oil passages can lead to premature wear or leaks.

Solution: Thoroughly clean all engine components before assembly. Use appropriate solvents and brushes, and ensure all oil passages are clear. Compressed air can be used for drying, but ensure it's filtered to prevent contamination.

2. Incorrect Torque Specifications:

Issue: Over-tightening or under-tightening bolts (e.g., cylinder head bolts, connecting rod bolts) can cause warpage, stripping of threads, or component failure.

Solution: Always consult the Komatsu service manual for the exact torque specifications for each fastener. Use a calibrated torque wrench and follow the specified tightening sequence (e.g., cross-pattern for cylinder heads).

3. Misalignment of Piston Rings:

Issue: If piston ring gaps are not staggered correctly during installation, it can lead to excessive blow-by, oil consumption, and reduced compression.

Solution: Ensure piston ring gaps are staggered at 120-degree intervals from each other and away from the piston pin bore during assembly. Use a piston ring compressor tool for smooth installation into the cylinder liner.

4. Insufficient Lubrication During Assembly:

Issue: Installing components without proper lubrication can cause dry starts, scuffing, and immediate damage upon initial engine startup.

Solution: Lubricate all bearing surfaces, piston skirts, cylinder liners, and camshaft lobes with clean engine oil or assembly lube prior to installation. This provides initial protection before the engine's oil system is fully pressurized.

5. Neglecting Break-in Procedure:

Issue: Skipping or improper engine break-in after an overhaul can lead to glazing of cylinder walls, poor ring seating, and premature wear.

Solution: Follow the manufacturer's recommended engine break-in procedure, typically involving varying RPMs and loads, and avoiding prolonged idling or full-throttle operation for the initial hours. Change oil and filter after the specified break-in period.