65.03901-0058 D1146 DE08 Head Gasket Kit for Doosan Engine Overhaul Kit

Support Alibaba online purchase

65.03901-0058 D1146 DE08 Head Gasket Kit for Doosan Engine Overhaul Kit

Ensure optimal performance and longevity for your Doosan engine with our high-quality Head Gasket Kit.

Product Overview

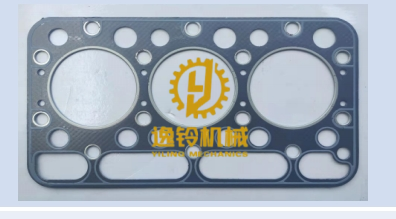

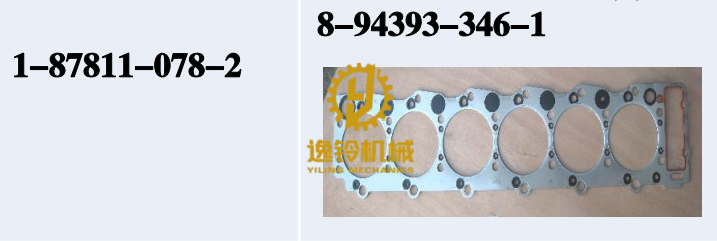

The 65.03901-0058 D1146 DE08 Head Gasket Kit is a crucial component for any comprehensive Doosan engine overhaul. Designed to meet or exceed OEM specifications, this kit provides a secure seal between the engine block and cylinder head, preventing leaks of combustion gases, coolant, and oil. Using a genuine-quality head gasket kit is essential for maintaining engine compression, preventing overheating, and ensuring the overall efficiency and reliability of your machinery.

Key Product Parameters

Part Number: 65.03901-0058

Alternative Part Number: D1146 DE08

Product Type: Head Gasket Kit

Engine Compatibility: Specifically designed for Doosan D1146 and DE08 series engines.

Material: High-grade composite materials for superior heat resistance and sealing capabilities.

Kit Contents: Typically includes multiple gaskets and seals required for a complete head gasket replacement.

Quality Assurance: Manufactured to strict quality control standards for durability and reliable performance.

Product Advantages and Selling Points

Precision Fit: Engineered for a perfect fit, ensuring optimal sealing and preventing costly leaks.

Durability: Constructed from robust materials that withstand extreme temperatures and pressures common in heavy-duty engine operation.

Enhanced Engine Performance: Restores proper compression, leading to improved fuel efficiency and power output.

Longevity: Extends the lifespan of your Doosan engine by maintaining ideal operating conditions.

Cost-Effective: A vital part of preventative maintenance that can save significant costs associated with major engine damage.

Applicable Equipment and Scenarios

This Head Gasket Kit is specifically designed for Doosan engines, commonly found in a wide range of heavy machinery and industrial equipment. These applications often demand high reliability and continuous operation, making proper engine maintenance crucial.

Construction Equipment: Doosan excavators (e.g., DX series), wheel loaders, and articulated dump trucks often utilize D1146/DE08 engines. These machines operate in demanding environments like construction sites, quarries, and mining operations, where engine integrity is paramount.

Industrial Generators: Many industrial power generation units and standby generators are powered by Doosan engines. These generators provide critical power for factories, hospitals, data centers, and remote sites, requiring absolute reliability.

Marine Applications: Certain Doosan marine engines for commercial fishing vessels, tugboats, and smaller cargo ships may also use these engine models. Consistent engine performance is vital for safe and efficient maritime operations.

Agricultural Machinery: Some larger agricultural equipment like combines and tractors might incorporate Doosan engines, operating through long hours in various field conditions.

Case Study Example:

A construction company experienced frequent overheating issues with their Doosan DX300LC excavator. Upon inspection, it was determined that the original head gasket had failed, leading to coolant leakage into the combustion chambers. By replacing the faulty gasket with the 65.03901-0058 D1146 DE08 Head Gasket Kit, the engine's compression was restored, and overheating was eliminated. The excavator returned to full operational capacity, preventing significant downtime and project delays.

Related Products

When performing a complete engine overhaul, it's often beneficial to consider replacing other related components to ensure comprehensive maintenance and prevent future issues.

Full Engine Gasket Set: Includes all necessary gaskets and seals for a complete engine rebuild. Applicable for a wide range of Doosan engine models beyond D1146/DE08, depending on the specific kit.

Cylinder Head Bolts: It's recommended to replace head bolts during a head gasket replacement as they are "torque-to-yield" and can stretch. Applicable for all Doosan engines requiring new head gaskets.

Oil Cooler Gaskets: Essential for maintaining the integrity of the engine's oil cooling system. Applicable for any Doosan engine with an oil cooler.

Valve Stem Seals: Prevents oil from leaking past the valve guides into the combustion chamber. Applicable for all Doosan engines undergoing valve train maintenance.

Piston Ring Sets: Crucial for maintaining compression and controlling oil consumption during a comprehensive overhaul. Applicable for various Doosan engine sizes and types.

Common Installation & Maintenance Issues and Solutions

Issue: Improper Torqueing of Head Bolts.

Solution: Always follow the manufacturer's specified torque sequence and values. Use a calibrated torque wrench and ensure bolts are tightened in stages to prevent uneven pressure distribution and gasket failure.Issue: Contaminated Sealing Surfaces.

Solution: Thoroughly clean and degrease both the engine block and cylinder head surfaces before installing the new gasket. Any debris or old gasket material can compromise the seal. Consider using a surface preparation tool for optimal results.Issue: Damaged Gasket During Installation.

Solution: Handle the new head gasket with care. Avoid bending, creasing, or tearing it. Ensure correct orientation as per the engine diagram.Issue: Reusing Old Head Bolts.

Solution: Doosan, like many engine manufacturers, specifies that head bolts are "torque-to-yield" and should be replaced with new ones during a head gasket job. Reusing old bolts can lead to insufficient clamping force and eventual gasket failure.Issue: Air Pockets in Cooling System After Reassembly.

Solution: Properly bleed the cooling system after refilling to remove any trapped air. Air pockets can lead to localized hot spots and potential future gasket damage.