65.03901-0076 Fit for Doosan Daewoo D2366 Cylinder Head Gasket

Support Alibaba online purchase

65.03901-0076 Cylinder Head Gasket for Doosan Daewoo D2366 Engine

Product Overview

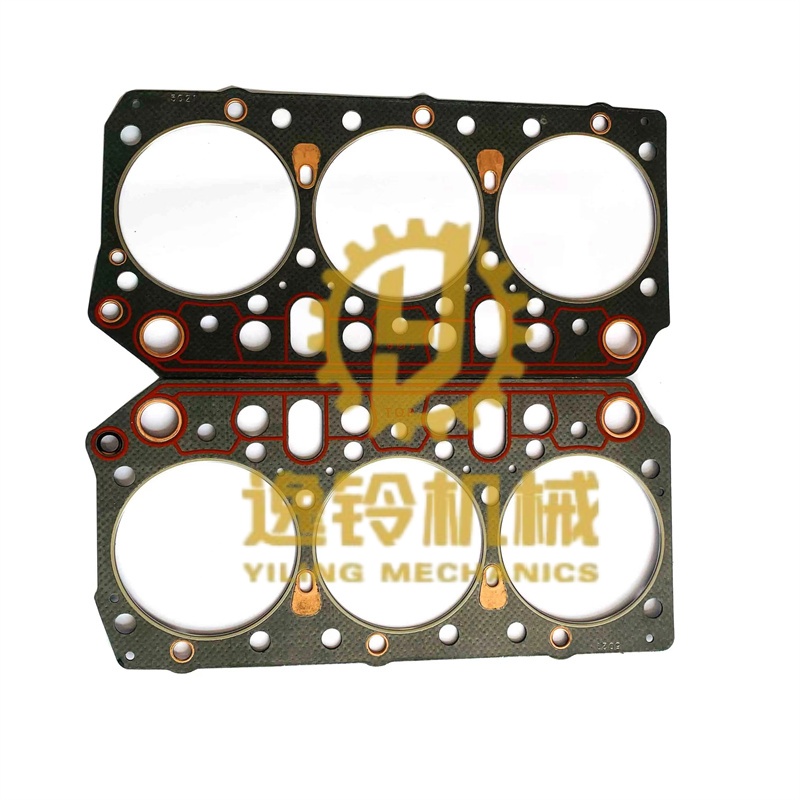

The 65.03901-0076 Cylinder Head Gasket is a high-quality replacement part specifically engineered for Doosan Daewoo D2366 engines. This critical component ensures a reliable seal between the cylinder head and the engine block, maintaining optimal engine compression and preventing leaks of coolant or oil. Crafted from durable, non-asbestos materials, it is designed to withstand the rigorous conditions of heavy-duty operations, contributing significantly to engine performance and longevity.

Key Product Parameters

Part Number: 65.03901-0076

Alternative Part Numbers: 65.03901-0051, 65.03901-0052, 65.03901-0075

Material: High-grade Non-Asbestos Composite

Application: Doosan Daewoo D2366 Engine

Condition: New

Seal Type: Multi-layer steel (MLS) or composite for superior sealing

Product Advantages and Selling Points

Reliable Sealing: Engineered to provide a robust and leak-proof seal, crucial for maintaining cylinder compression and preventing fluid contamination.

Optimal Engine Performance: Ensures proper combustion efficiency, contributing to the engine's power output and fuel economy.

Enhanced Longevity: Manufactured from high-quality, durable materials that withstand high temperatures and pressures, extending the lifespan of your engine.

Perfect Fit: Designed as an OEM-standard replacement, guaranteeing precise fitment for Doosan Daewoo D2366 engines, simplifying the installation process.

Pressure Resistance: Exhibits excellent performance under extreme operating conditions and high engine pressures.

Applicable Equipment

This 65.03901-0076 cylinder head gasket is specifically designed for the Doosan Daewoo D2366 engine. This robust engine is widely utilized in various heavy-duty equipment, including:

Construction Machinery: Excavators (e.g., Doosan Daewoo DH280, DH320), Wheel Loaders.

Heavy-Duty Trucks: Such as Daewoo Novus and Daewoo Puma models.

Buses and Coaches.

Forklifts.

Industrial Generators.

Application Scenarios and Case Analysis

The Doosan Daewoo D2366 engine, with its impressive power output and high torque, is a powerhouse in demanding environments. The reliability of components like the cylinder head gasket is paramount in ensuring consistent performance across diverse applications:

Excavation Projects: In large-scale construction sites, D2366-powered excavators (like the DH280 and DH320) are integral for digging foundations, trenching, and earthmoving. A properly sealed cylinder head gasket ensures the engine maintains full compression, delivering the necessary power and torque for efficient material removal, even in tough soil or rock conditions. Case: A D2366 excavator working on a highway expansion project maintained consistent digging force for long shifts, crucial for meeting project deadlines, attributed to its well-maintained engine components, including a robust cylinder head gasket preventing pressure loss.

Grading and Landscaping: For precision tasks like road construction, site preparation, and agricultural land leveling, D2366 engines in graders or wheel loaders offer smooth power delivery and precise control. A reliable gasket prevents any internal leaks that could degrade engine performance, ensuring consistent output for fine grading work. Case: A Doosan wheel loader with a D2366 engine was used for a major land development project, precisely leveling large areas. The stable engine performance, supported by an intact cylinder head gasket, allowed for accurate and uniform grading, minimizing rework.

Demolition Operations: The high torque output of the D2366 makes it suitable for heavy-duty demolition of concrete structures, walls, and other robust materials. The cylinder head gasket's durability under high-stress situations is critical to prevent engine failure during intense demolition work. Case: During the demolition of an old industrial building, a D2366-powered machine consistently provided the brute force needed to break down thick concrete slabs. Its engine's integrity, ensured by a reliable gasket, was vital for handling the immense, fluctuating loads without compromise.

Related Similar Products

In addition to the cylinder head gasket, we offer a comprehensive range of engine components compatible with Doosan Daewoo D2366 and other Doosan/Daewoo engines, ensuring complete engine overhaul and maintenance solutions:

Piston Sets: For D2366, DE12TIS engines. Essential for engine compression and power generation.

Piston Rings: For D2366, DE12TIS. Crucial for sealing combustion chambers, oil control, and heat transfer.

Main and Con Rod Bearings: For D2366, DE12TI, DE12TIS engines. Support crankshaft and connecting rod rotation.

Engine Overhaul Kits: Comprehensive kits including gaskets, pistons, rings, and bearings for D2366, DE12TIS, DB58, D1146, DL08 engines.

Valves (Intake & Exhaust): For D2366, DE12TIS. Regulate air-fuel mixture and exhaust gas flow.

Fuel and Oil Filters: For various Doosan engines including DE12, DE12TIS. Maintain fuel and oil cleanliness.

Cylinder Liners: For D2366, DE12TI engines. Provide the cylinder walls for piston movement.

Installation and Maintenance: Common Issues & Solutions

Proper installation and ongoing maintenance are vital for the longevity and performance of your cylinder head gasket. Here are common issues and their solutions:

Issue: Engine Overheating

This is the primary cause of cylinder head gasket failure, leading to gasket material degradation and potential head warping. Symptoms include white smoke from exhaust (coolant burning), coolant/oil mixing (sludge in oil), and rapid coolant loss.

Solution: Regularly check and maintain the cooling system (thermostat, radiator, hoses, coolant level and type). Monitor the engine temperature gauge vigilantly. Address any overheating promptly by shutting down the engine to prevent severe damage. Ensure adequate engine oil levels and timely oil changes to help dissipate heat.

Issue: Improper Surface Preparation or Torquing

Imperfections on the engine block or cylinder head surfaces, or incorrect tightening (torquing) of head bolts, can lead to an ineffective seal and premature gasket failure.

Solution: During installation, ensure both the cylinder head and engine block surfaces are meticulously cleaned and inspected for flatness and smoothness. Professional machining may be required to achieve the manufacturer's specified surface finish. Always use a calibrated torque wrench and follow the engine manufacturer's specific torquing sequence and specifications. Consider using a quality gasket sealant or aluminum spray paint on the gasket surfaces for better bonding.

Issue: Low-Quality Replacement Parts / Aggressive Operation

Using substandard gaskets or consistently subjecting the engine to excessive loads and aggressive driving can lead to premature wear and failure.

Solution: Always opt for high-quality, OEM or equivalent cylinder head gaskets and other engine components. Adhere to the manufacturer's recommended load limits for the vehicle/equipment. Drive smoothly, avoiding excessive acceleration and high engine speeds, especially when the engine is cold, to reduce stress on engine components.