6D95 S6D95 SA6D95L full overhaul gasket kit for Komatsu engine PC120-3 excavator

Support Alibaba online purchase

Komatsu 6D95 S6D95 SA6D95L Full Overhaul Gasket Kit for PC120-3 Excavator

Product Overview

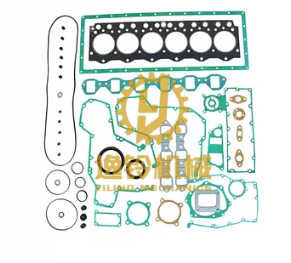

Ensure the longevity and optimal performance of your Komatsu engine with our premium Full Overhaul Gasket Kit. Specifically designed for Komatsu 6D95, S6D95, and SA6D95L engines, this comprehensive kit provides all the necessary gaskets, seals, and O-rings for a complete engine overhaul. Crafted from high-quality materials, our gasket kit guarantees a perfect fit and superior sealing, preventing leaks and maintaining peak engine efficiency. Ideal for heavy-duty applications, this kit is your reliable solution for engine restoration and preventative maintenance.

Product Parameters

Product Name: Full Overhaul Gasket Kit

Engine Models: Komatsu 6D95, S6D95, SA6D95L

Compatible Equipment: Komatsu PC120-3 Excavator

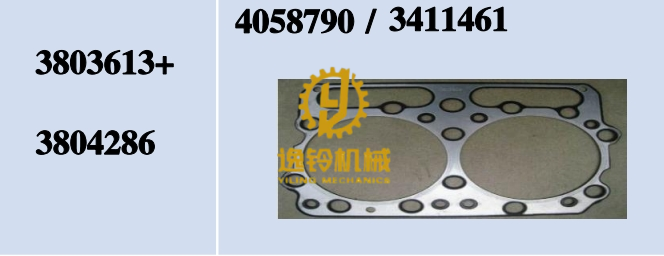

Kit Contents: Head gasket, manifold gaskets, valve cover gaskets, oil pan gasket, front and rear crankshaft seals, valve stem seals, O-rings, and other necessary seals for a complete overhaul.

Material: High-quality, durable composite materials, rubber, and metal for superior sealing and heat resistance.

Packaging: Secure, protective packaging to ensure product integrity during transit.

Key Advantages & Selling Points

100% Compatibility: Engineered specifically for Komatsu 6D95, S6D95, and SA6D95L engines, guaranteeing a precise fit and seamless installation.

Superior Sealing Performance: Manufactured with high-grade materials that resist extreme temperatures, pressures, and chemical exposure, preventing leaks and ensuring optimal engine compression.

Extended Engine Lifespan: A complete overhaul with our kit restores engine efficiency, reduces wear and tear, and significantly prolongs the service life of your Komatsu engine.

Cost-Effective Solution: Avoid costly engine replacements by performing a thorough overhaul. Our kit provides all necessary components in one package, saving you time and money.

Reliability & Durability: Each component is rigorously tested to meet or exceed OEM specifications, ensuring unmatched reliability and long-term durability in demanding operating conditions.

Applicable Equipment & Scenarios

This full overhaul gasket kit is primarily designed for the Komatsu PC120-3 Excavator, a versatile and widely used piece of heavy machinery.

Application Scenarios & Case Analysis:

Construction Sites: PC120-3 excavators are workhorses in general construction, used for digging foundations, trenching for utilities, and site preparation. A worn engine gasket can lead to power loss, increased fuel consumption, and potential engine failure, halting critical project timelines. Overhauling the engine with this kit ensures the excavator operates at peak efficiency, minimizing downtime and keeping construction projects on schedule.

Road Building & Maintenance: These excavators are essential for road construction, including excavation for new roads, grading, and material handling. The harsh environments and continuous operation demand a robust engine. Regular engine overhauls using our gasket kit prevent oil leaks, maintain proper compression, and protect against overheating, crucial for sustained performance during long shifts.

Quarrying & Mining Operations: In quarrying and small-scale mining, PC120-3 excavators are used for extracting raw materials, loading trucks, and site clearance. The engines in these environments are subjected to extreme dust and heavy loads. A complete gasket replacement is vital for sealing against abrasive particles and maintaining engine integrity under immense stress, preventing costly breakdowns in remote locations.

Demolition Projects: For small to medium-scale demolition, the PC120-3 is utilized for breaking down structures and clearing debris. This involves continuous strenuous work that puts significant strain on the engine. An engine overhaul with our high-quality gaskets ensures the engine can withstand the demanding cycles of demolition, providing consistent power and preventing unforeseen mechanical failures.

Related Products

Beyond our full overhaul gasket kit, we offer a range of related engine components and kits to support your Komatsu machinery:

Top End Gasket Kits: Ideal for cylinder head repairs or valve train maintenance, focusing on the upper part of the engine.

Applicable Equipment: Komatsu PC120-3, PC130-7, WA150, GD510R (with 6D95, S6D95, SA6D95L engines).Bottom End Gasket Kits: Designed for crankshaft, main bearing, and oil pan related repairs.

Applicable Equipment: Komatsu PC120-3, PC100-6, D31, D37 (with 6D95, S6D95, SA6D95L engines).Individual Engine Gaskets & Seals: For targeted repairs or specific component replacements, such as cylinder head gaskets, oil seals, or O-rings.

Applicable Equipment: Any Komatsu machinery utilizing 6D95, S6D95, SA6D95L engines (e.g., excavators, bulldozers, wheel loaders).Engine Bearing Kits: Includes main bearings, connecting rod bearings, and thrust washers for complete lower engine refurbishment.

Applicable Equipment: Komatsu PC120-3, PC100-6, GD510R (with 6D95, S6D95, SA6D95L engines).Engine Piston & Liner Kits: For restoring engine compression and efficiency by replacing critical combustion components.

Applicable Equipment: Komatsu PC120-3, WA150, GD510R (with 6D95, S6D95, SA6D95L engines).

Installation & Maintenance: Common Issues & Solutions

Proper installation and regular maintenance are crucial for the longevity of your Komatsu engine and the effectiveness of the gasket kit.

Common Issues:

Gasket Leaks After Installation: Often caused by improper torqueing sequences, dirty mating surfaces, or damaged gasket surfaces.

Overheating: Can be a symptom of a blown head gasket, leading to coolant loss and combustion gas entering the cooling system.

Reduced Engine Performance: Loss of compression due to worn or failed gaskets can lead to decreased power, increased fuel consumption, and rough idling.

Oil Contamination: Coolant mixing with oil or vice versa, indicating internal gasket failure (e.g., head gasket).

Premature Gasket Failure: Can result from using incorrect sealants, overtightening, or insufficient surface preparation.

Solutions:

Thorough Surface Preparation: Before installing new gaskets, ensure all mating surfaces are meticulously clean, free of old gasket material, corrosion, and debris. Use appropriate cleaning agents and fine abrasives if necessary, but avoid damaging the surface.

Follow Torque Specifications: Always refer to the Komatsu service manual for the exact torque specifications and tightening sequence for all bolts associated with gasket installation (e.g., cylinder head bolts). Improper torqueing is a primary cause of leaks.

Inspect for Warping/Cracks: Before reassembly, inspect critical components like the cylinder head and engine block for any signs of warping or cracks. These can prevent a proper seal even with new gaskets. Machining or replacement may be necessary.

Use Correct Sealants (If Required): Some gaskets require a thin, even coat of RTV silicone sealant, while others are designed for dry installation. Always follow the manufacturer's recommendations.

Systematic Testing: After overhaul, perform thorough system checks, including pressure testing the cooling system and observing for oil or coolant leaks during initial engine run. Monitor engine temperature and performance closely.

Regular Maintenance: Adhere to regular engine oil and coolant changes, and periodically inspect for any signs of external leaks or unusual engine noises. Early detection can prevent minor issues from escalating.