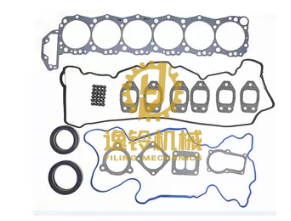

S6D105 Cylinder Head Gasket Set , Engine Overhaul Gasket Kit 6137-K1-3012 6137-K2-3005

Support Alibaba online purchase

S6D105 Cylinder Head Gasket Set & Engine Overhaul Kit

Product Overview

Ensure the longevity and optimal performance of your heavy-duty machinery with our premium S6D105 Cylinder Head Gasket Set and comprehensive Engine Overhaul Gasket Kit. Specifically engineered to meet stringent OEM standards, this kit provides all necessary gaskets and seals for a complete engine overhaul, ensuring a perfect fit and leak-free operation. Designed for durability and reliability, it is the ideal solution for maintaining the efficiency and power of your equipment.

Product Specifications

Part Numbers: 6137-K1-3012 (Cylinder Head Gasket Set), 6137-K2-3005 (Engine Overhaul Gasket Kit)

Engine Model Compatibility: S6D105

Material: High-quality, heat-resistant, and durable composite materials for optimal sealing and longevity.

Contents: Includes all cylinder head gaskets, manifold gaskets, valve stem seals, oil pan gaskets, front and rear crankshaft seals, and other essential seals required for a full engine overhaul.

Standards: Manufactured to meet or exceed OEM specifications for fit, form, and function.

Key Advantages & Selling Points

Superior Sealing Performance: Engineered to prevent leaks and maintain optimal engine compression, extending engine life.

Durable Construction: Made from robust materials resistant to high temperatures and pressures, ensuring long-term reliability.

Comprehensive Kit: Includes all necessary components for a complete overhaul, saving time and simplifying the repair process.

Exact Fit: Designed to precise dimensions for seamless installation and perfect compatibility with S6D105 engines.

Cost-Effective Solution: A reliable alternative to OEM parts, offering significant savings without compromising on quality.

Applicable Equipment & Applications

This S6D105 Cylinder Head Gasket Set and Engine Overhaul Gasket Kit is specifically designed for various heavy-duty machinery equipped with the S6D105 engine. This includes, but is not limited to:

Komatsu Excavators: Such as the PC200-5, PC220-5, PC200-6, PC220-6 models.

Komatsu Wheel Loaders: Including WA200-5, WA250-5 series.

Komatsu Bulldozers: Specific models utilizing the S6D105 engine.

Other Heavy Construction Equipment: Any machinery that relies on the robust performance of the S6D105 engine.

Application Scenarios & Case Analysis:

These machines are workhorses in demanding environments, making reliable engine components crucial.

Construction Sites: Excavators and bulldozers with S6D105 engines are fundamental for earthmoving, trenching, and material handling. A worn gasket kit can lead to engine overheating and power loss, halting critical project timelines. Our kit ensures these machines operate continuously without interruptions.

Case Study: A construction company reported consistent overheating in their Komatsu PC200-6. Diagnosis revealed a failed cylinder head gasket. Replacement with our S6D105 kit immediately resolved the issue, preventing costly downtime and keeping the project on schedule.Mining Operations: Wheel loaders and excavators are essential for moving vast quantities of ore and overburden. The extreme conditions in mines necessitate robust and reliable engine components. Our gasket kit provides the necessary seal integrity to withstand high dust and temperature environments.

Case Study: A mining fleet was experiencing reduced fuel efficiency and power in their Komatsu WA250-5 loaders. An engine overhaul, including our gasket kit, restored optimal engine performance, leading to improved fuel economy and increased operational output.Infrastructure Development: From road construction to bridge building, S6D105-powered machinery is vital. The precision and reliability of engine gaskets are paramount to ensure these complex projects proceed smoothly.

Case Study: During a major highway expansion, a Komatsu PC220-5 excavator developed an oil leak. Identifying a deteriorated oil pan gasket, quick replacement with a component from our overhaul kit prevented significant environmental contamination and maintained continuous progress on the project.

Related Products

To complement your engine maintenance needs, consider these related products, also available for various Komatsu engine models:

S6D95 Engine Overhaul Gasket Kit: Suitable for Komatsu PC100-5, PC120-5 excavators.

4D95 Cylinder Head Gasket Set: Ideal for Komatsu PC60-7, PC78US-6, PC75UU-2 excavators and other compact equipment.

6D125 Engine Full Gasket Set: For larger Komatsu excavators like the PC300-6, PC400-6, and certain wheel loaders.

S6D102 Engine Rebuild Kit: Comprehensive kit for Komatsu PC200-7, PC220-7, PC200-8, PC220-8 excavators.

Installation & Maintenance Tips

Common Issues & Solutions:

Issue: Engine Overheating / Coolant Leaks:

This is often a symptom of a failing cylinder head gasket.

Solution: Replace the cylinder head gasket following manufacturer torque specifications. Ensure the cylinder head surface is clean, flat, and free of imperfections before installation. Always use new head bolts if recommended by the engine manual.Issue: Oil Leaks (External/Internal):

Visible oil leaks from the oil pan or valve cover, or oil mixing with coolant, indicate gasket failure.

Solution: Identify the source of the leak and replace the corresponding gasket (e.g., oil pan gasket, valve cover gasket, or cylinder head gasket for internal leaks). Clean all mating surfaces thoroughly and apply a thin bead of RTV sealant if specified.Issue: Reduced Engine Compression / Power Loss:

A damaged cylinder head gasket can lead to loss of compression between cylinders or into the cooling system.

Solution: Perform a compression test to confirm. If low compression is detected, a complete engine overhaul, including the cylinder head gasket and valve seals, is necessary. Ensure proper valve lash adjustment after reassembly.Installation Best Practices:

Always refer to the specific Komatsu service manual for torque specifications and tightening sequences.

Thoroughly clean all mating surfaces before installing new gaskets.

Inspect cylinder head and engine block for warpage or cracks.

Lubricate relevant components (e.g., valve stems) before assembly.

Use appropriate tools and ensure proper alignment of parts.