For Komatsu Diesel Engine 6D125 PC400-7 Complete Gasket Repair Kit

Support Alibaba online purchase

Komatsu Diesel Engine 6D125 PC400-7 Complete Gasket Repair Kit

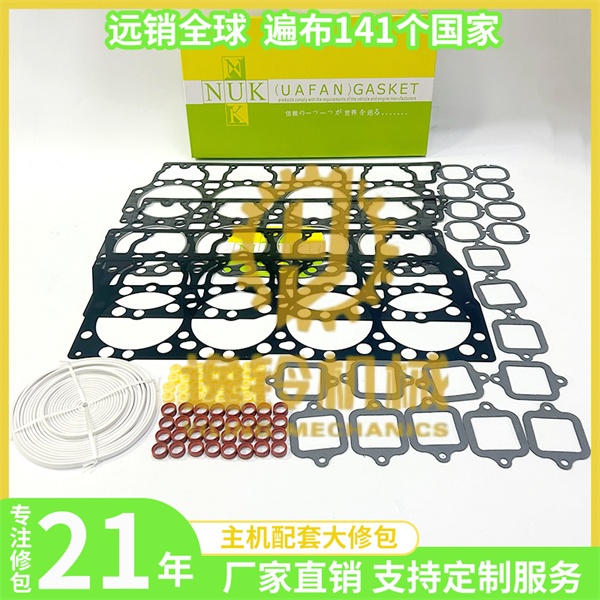

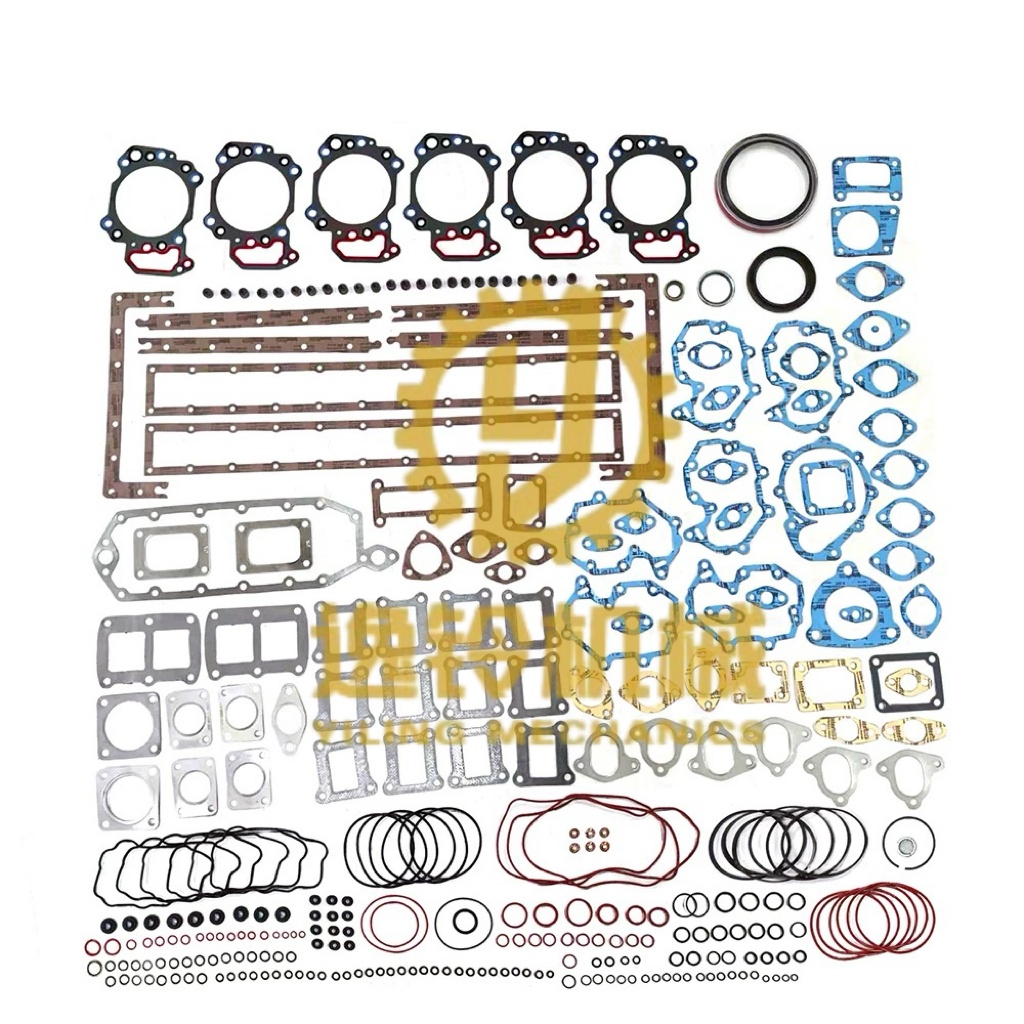

Ensure peak performance and extend the lifespan of your Komatsu heavy machinery with our premium Complete Gasket Repair Kit for the Komatsu Diesel Engine 6D125 and PC400-7 models. This meticulously assembled kit provides all the necessary gaskets, seals, and O-rings required for a comprehensive engine overhaul or major repair, preventing leaks and maintaining optimal engine compression. Engineered to meet or exceed OEM specifications, our kit guarantees a perfect fit and reliable sealing performance for demanding operating conditions.

Product Parameters

Product Type: Complete Gasket Repair Kit

Engine Model Compatibility: Komatsu 6D125 Series Diesel Engines

Equipment Model Compatibility: Komatsu PC400-7 Excavator, and other equipment utilizing the 6D125 engine

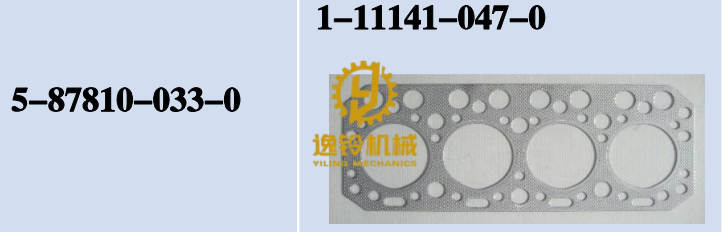

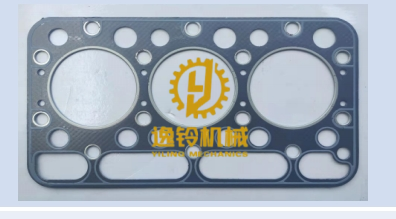

Kit Contents: Includes cylinder head gasket, valve stem seals, oil pan gasket, timing cover gasket, manifold gaskets (intake/exhaust), O-rings, and various other essential seals for a full engine repair. (Specific contents may vary slightly based on production batch.)

Material Quality: High-grade, durable materials resistant to extreme temperatures, pressure, and various engine fluids.

Standards: Manufactured to meet or exceed OEM specifications for fit, form, and function.

Product Advantages & Selling Points

Comprehensive Solution: Everything you need for a complete engine reseal in one convenient kit, saving time and hassle in sourcing individual components.

OEM-Level Quality: Components are manufactured with precision and from robust materials, ensuring a tight seal and long-lasting durability under heavy-duty operation.

Optimized Performance: Prevents oil leaks, coolant leaks, and maintains proper engine compression, leading to improved fuel efficiency and sustained power output.

Cost-Effective Repair: A complete kit reduces the risk of overlooking a necessary seal, preventing potential future costly repairs.

Reliability: Designed for the rigorous demands of Komatsu heavy equipment, ensuring your machinery operates reliably in tough environments.

Applicable Equipment

This Complete Gasket Repair Kit is specifically designed for the Komatsu 6D125 series diesel engine. This engine is commonly found in a range of Komatsu heavy equipment, including but not limited to:

Komatsu PC400-7 Excavator

Komatsu PC450 Excavator

Komatsu WA470 Wheel Loader

Komatsu HD325 Dump Truck

Various other Komatsu construction, mining, and industrial machinery powered by the 6D125 engine.

Application Scenarios & Case Analysis

Komatsu machinery equipped with the 6D125 engine operates in some of the most challenging environments globally. Ensuring these engines are leak-free and maintain optimal compression is critical for operational efficiency and safety.

Construction Sites: Excavators like the PC400-7 are workhorses in large-scale construction projects, from digging foundations for skyscrapers to earthmoving for road construction. A leaking engine can lead to downtime, costly fluid consumption, and environmental hazards. Using our complete gasket kit during scheduled maintenance or after high operating hours ensures the engine remains sealed, preventing costly delays and ensuring projects stay on schedule.

Mining Operations: In open-pit mines, dump trucks and large excavators run continuously, often in dusty, abrasive conditions and extreme temperatures. An engine gasket failure can lead to severe engine damage, resulting in massive production losses. A proactive approach with our reliable gasket kit during engine rebuilds or major repairs is vital for maintaining uptime and maximizing ore extraction rates.

Quarrying and Aggregates: Wheel loaders and excavators are essential for handling aggregates, breaking rock, and loading materials. The constant vibration and heavy loads put immense stress on engine components. Our high-quality gaskets ensure that the engine remains sealed, preventing leaks that could contaminate the site or lead to engine failure, thereby ensuring consistent material flow and operational safety.

Related Similar Products

Beyond this specific kit, we offer a wide range of engine repair solutions. Here are some related products and their applicable equipment:

Komatsu 6D107 Engine Overhaul Gasket Kit: For Komatsu PC200-8, PC210-8 Excavators, and other machines using the 6D107 engine.

Komatsu SA6D140 Engine Full Gasket Set: Applicable for larger Komatsu machinery like PC600-7, PC650-8 Excavators, and Komatsu D375-5 Dozers.

Caterpillar C9 Engine Gasket Kit: Essential for Caterpillar excavators (330D, 336D), wheel loaders (962H), and other C9 powered equipment.

Cummins QSM11 Engine Gasket Set: For Cummins-powered equipment, including certain models of large excavators, dozers, and power generators.

Individual Engine Gaskets and Seals: We also supply specific components like cylinder head gaskets, oil pan gaskets, valve stem seals, etc., for a variety of engine models and brands.

Common Installation & Maintenance Issues & Solutions

Proper installation and regular maintenance are crucial for the longevity of your engine gaskets. Here are some common issues and their solutions:

Issue: Premature Gasket Failure/Leaks after Installation.

Solution: This is often due to improper surface preparation (not cleaning thoroughly or removing old gasket material completely), incorrect torque sequence/specs for bolts, or re-using old bolts. Always ensure mating surfaces are perfectly clean and flat. Follow the manufacturer's torque specifications and sequence meticulously. Use new bolts when required (e.g., stretch bolts for cylinder heads).Issue: Gasket Swelling or Deterioration.

Solution: Can be caused by using incompatible coolants, oils, or fuel, or by consistent overheating. Ensure you are using the correct type and quality of fluids specified for your Komatsu engine. Address any cooling system issues promptly to prevent overheating.Issue: Oil or Coolant Weepage from Gasket Edges.

Solution: Often a sign of insufficient clamping force or an unevenly torqued component. Re-check torque settings, especially after initial engine run-in if a specific re-torque procedure is recommended. Ensure the correct gasket type (e.g., composite, multi-layer steel) is used for the application.Issue: Difficulty Seating Gaskets.

Solution: Ensure the gasket is oriented correctly. Some gaskets are side-specific. Lightly apply a thin layer of appropriate gasket sealant only if recommended by the manufacturer, or for specific areas like corners. Avoid excessive sealant, which can cause blockages.