6D125 Engine overhaul Full Gasket Set 6150-11-1812 for Komatsu 6D125 6D125-1 6D125-1A 6D125-1B-P Engine Land grader GD663A-2

Support Alibaba online purchase

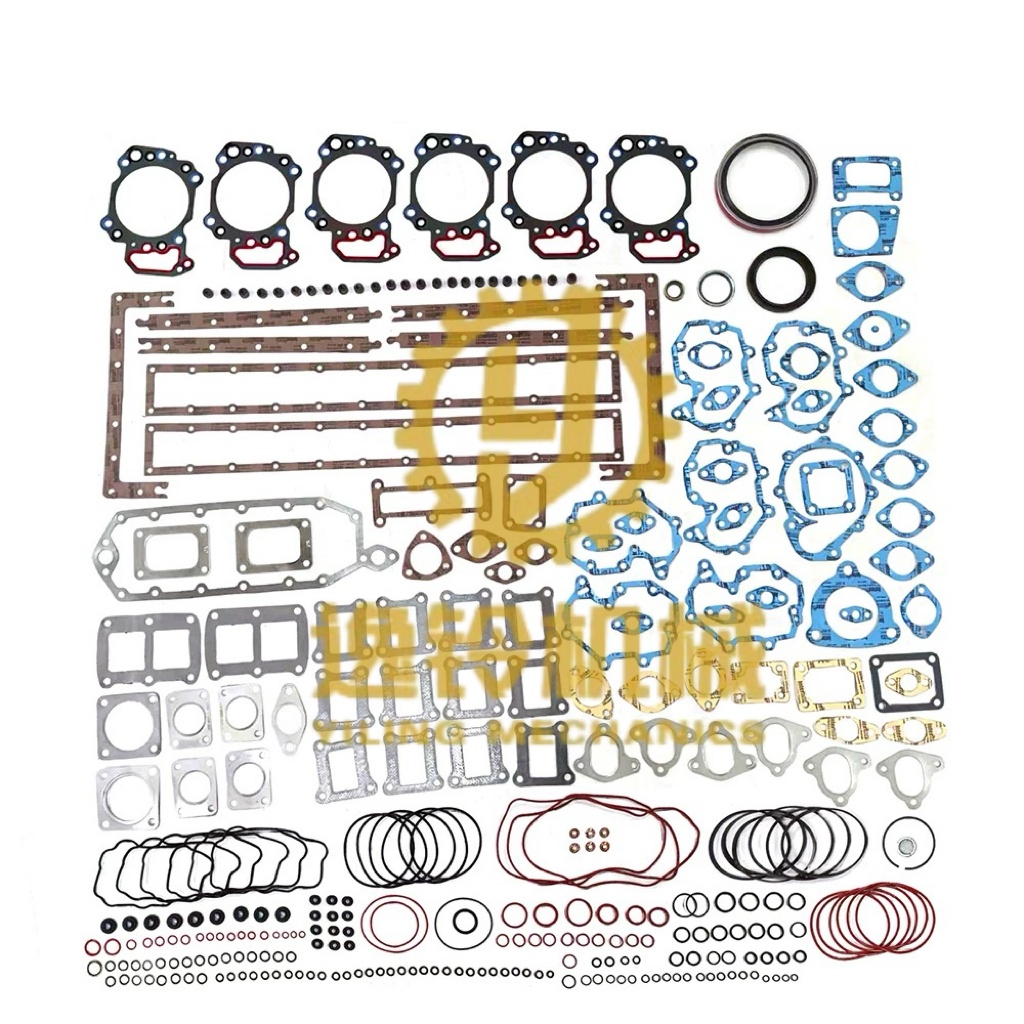

6D125 Engine Overhaul Full Gasket Set 6150-11-1812 for Komatsu 6D125 Series Engines

Product Overview

Ensure the longevity and optimal performance of your Komatsu engine with our premium 6D125 Engine Overhaul Full Gasket Set. This comprehensive kit, with part number 6150-11-1812, is specifically designed for Komatsu 6D125, 6D125-1, 6D125-1A, and 6D125-1B-P engines, providing all necessary gaskets and seals for a complete and reliable engine overhaul.

A full gasket set is crucial for maintaining proper sealing within the engine, preventing leaks of vital fluids like oil and coolant, and ensuring consistent compression. Our gasket set is manufactured to meet or exceed OEM specifications, guaranteeing a precise fit and durable performance for demanding applications.

Key Features & Product Advantages

Comprehensive Kit: Includes all necessary gaskets and seals for a complete engine overhaul, ensuring all critical sealing points are addressed.

OEM Quality & Fit: Engineered to match the exact specifications of Komatsu 6D125 series engines, providing a perfect fit and reliable seal.

Durable Materials: Manufactured from high-quality, heat-resistant, and resilient materials designed to withstand extreme engine conditions and prevent premature wear.

Restores Engine Performance: A new gasket set prevents leaks and maintains optimal engine compression, leading to improved fuel efficiency and power output.

Extends Engine Lifespan: Proper sealing protects internal engine components from contamination and wear, significantly extending the operational life of your Komatsu engine.

Cost-Effective Solution: A full gasket set is a cost-effective way to restore engine integrity during an overhaul, preventing more costly repairs down the line.

Product Parameters (Typical for a Full Gasket Set)

Part Number: 6150-11-1812

Engine Model Compatibility: Komatsu 6D125, 6D125-1, 6D125-1A, 6D125-1B-P

Type: Full Engine Overhaul Gasket Set

Contents: Includes head gasket, manifold gaskets, valve cover gaskets, oil pan gasket, front and rear main seals, valve stem seals, timing cover gasket, water pump gasket, and various O-rings and small seals. (Exact contents may vary slightly based on specific engine variant and kit configuration.)

Material: Multi-layered steel (MLS), graphite, rubber, silicone, and other high-grade composite materials.

Applicable Equipment & Application Scenarios

This 6D125 Engine Overhaul Full Gasket Set is primarily designed for Komatsu 6D125 series engines, which are widely utilized in heavy-duty construction and industrial machinery. Specifically, it is ideal for maintaining and overhauling the engine of the Komatsu Land Grader GD663A-2, as well as various models of Komatsu excavators (e.g., PC400-5, PC350-7, PC400-6, PC400-7, PC450-6, PC450-7, PC460-7) and other industrial equipment powered by the Komatsu 6D125 engine.

Application Scenarios & Case Analysis:

Road Construction & Maintenance: The Komatsu GD663A-2 motor grader is a critical machine for road projects. It excels in precise road grading and leveling, creating flat bases for new roads and restoring existing ones that have become uneven.

Case Example: In a large-scale highway expansion project, a Komatsu GD663A-2 is used for subgrade preparation. An engine overhaul with a new gasket set ensures the grader can maintain its high-accuracy surface finishing capabilities, preventing downtime and ensuring project deadlines are met.Ditching & Sloping: Graders, including the GD663A-2, are perfect for cutting trenches and drains along road sides or within work areas. Their adjustable blades allow for precise control over soil slope and gradient, creating stable, erosion-resistant structures.

Case Example: During a civil engineering project for water management, the GD663A-2 is instrumental in creating drainage ditches. The reliable performance provided by a well-maintained engine, using our gasket set, is crucial for continuous operation in challenging wet conditions.Land Reclamation & Site Preparation: The ability of motor graders to level ground and create slopes makes them suitable for land reclamation projects, redistributing soil and rocks to form new land areas, or leveling uneven terrain after excavation or mining.

Case Example: Post-mining operations often require significant land restoration. A Komatsu 6D125-powered machine equipped with a fully sealed engine helps ensure efficient and continuous ground leveling, preparing the site for future development or environmental rehabilitation.Mining & Quarrying Operations: Komatsu 6D125 engines power a range of equipment beyond graders, including large excavators and loaders, which are essential for material handling and excavation in mining and quarry environments.

Case Example: An excavator with a Komatsu 6D125 engine is operating in a quarry, constantly moving heavy rock. The extreme conditions demand a robust engine. Regular overhauls with high-quality gaskets prevent fluid leaks and maintain engine integrity, ensuring the excavator can withstand the continuous heavy load and dust.

Related Products for Komatsu 6D125 Engine Overhauls

When performing an engine overhaul, it's often advisable to inspect and replace other critical components to ensure complete reliability and performance. Here are some related products often used alongside a full gasket set for Komatsu 6D125 engines:

Cylinder Liners, Pistons, and Piston Rings: Essential components for maintaining proper compression and combustion.

Applicable Equipment: Komatsu Excavators (PC400, PC450 series), Komatsu Land Graders (GD663A-2), Komatsu Wheel Loaders, and various other industrial machines with 6D125 engines.Engine Bearings (Main, Connecting Rod, Thrust Washer Sets): Crucial for smooth crankshaft and connecting rod rotation, minimizing friction.

Applicable Equipment: Any equipment fitted with a Komatsu 6D125 engine, ensuring the critical rotating assemblies are properly supported.Engine Valves (Intake & Exhaust) and Valve Guides/Seats: Key to proper air intake and exhaust gas expulsion, critical for engine breathing and efficiency.

Applicable Equipment: All Komatsu machinery utilizing the 6D125 engine, vital for combustion cycle integrity.Water Pumps & Oil Pumps: Ensure efficient cooling and lubrication throughout the engine.

Applicable Equipment: Excavators, graders, and other heavy equipment powered by Komatsu 6D125, maintaining critical fluid circulation.Fuel Injectors & Turbochargers: For optimal fuel delivery and forced induction, enhancing engine power and efficiency.

Applicable Equipment: Performance-critical Komatsu equipment such as large excavators and heavy-duty loaders with 6D125 engines.Crankshafts & Camshafts: Core components for engine timing and power generation.

Applicable Equipment: Any heavy-duty Komatsu machinery requiring major engine rebuilds involving the 6D125 engine.

Installation & Maintenance: Common Issues and Solutions

Proper installation and ongoing maintenance are vital for the longevity of your engine and the effectiveness of a new gasket set. Here are some common problems encountered during installation and maintenance, along with their solutions:

Common Installation Mistakes & Solutions:

Failure to Check for Damage/Warpage:

Problem: Engine block or cylinder head surfaces may be warped or damaged from overheating. Installing a new gasket on an uneven surface will lead to leaks.

Solution: Always inspect mating surfaces for flatness and damage. Machine or replace components if excessive warpage is present.Incorrect Parts:

Problem: Using a gasket that is not specifically designed for the Komatsu 6D125 engine model.

Solution: Double-check part numbers and ensure the gasket set matches your specific engine variant (6D125, 6D125-1, etc.).Unclean Mating Surfaces & Bolt Holes:

Problem: Residue, old gasket material, oil, or coolant in bolt holes or on mating surfaces can prevent a proper seal.

Solution: Thoroughly clean all surfaces and bolt holes before installation. Ensure bolt threads are clean and free of galling.Incorrect Placement/Orientation:

Problem: Directional gaskets installed incorrectly, or misalignment during assembly.

Solution: Pay close attention to gasket orientation. Use dowel pins and locating pins to ensure perfect alignment.Improper Torque & Fastener Use:

Problem: Bolts that are too loose or too tight, or incorrect use of sealants/lubricants.

Solution: Always follow the manufacturer's specified torque settings and sequence for cylinder head and other critical bolts. Only use sealants or lubricants where explicitly recommended.

Common Post-Installation/Maintenance Issues & Solutions:

Engine Overheating:

Problem: Often indicates air pockets in the cooling system due to insufficient bleeding or a persistent cooling system issue.

Solution: Properly bleed the cooling system after refilling. Inspect the radiator, thermostat, and coolant levels. Address any underlying overheating causes immediately.Coolant Leaks or Oil Contamination (Milky Oil/Frothy Coolant):

Problem: Indicates the new gasket is not sealing correctly, or there are undetected cracks in the engine block/cylinder head.

Solution: Re-check torque on head bolts. If leaks persist, perform thorough diagnostics to identify the exact source of contamination or leakage, which may require re-inspection of mating surfaces.Poor Engine Performance / Compression Loss:

Problem: Can stem from an incorrect gasket, improper installation, or unaddressed damage to cylinders/pistons.

Solution: Verify correct gasket installation and proper torquing. Conduct a compression test to pinpoint affected cylinders and further diagnose.Excessive Exhaust Smoke (White Smoke):

Problem: Often a sign of coolant burning in the combustion chamber due to a compromised head gasket.

Solution: This requires immediate attention and re-diagnosis of the head gasket seal or potential internal engine damage.

By adhering to best practices during installation and being vigilant for these common signs, you can ensure a successful engine overhaul and maximize the life of your Komatsu 6D125 engine.