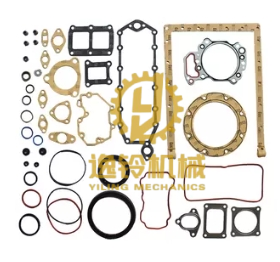

Steel Komatsu S6D125 Engine Full Overhaul Gasket Kits 6151-K1-3000

Support Alibaba online purchase

Steel Komatsu S6D125 Engine Full Overhaul Gasket Kits 6151-K1-3000

Product Overview

Ensure the longevity and optimal performance of your Komatsu S6D125 engine with our premium Steel Full Overhaul Gasket Kit, part number 6151-K1-3000. This comprehensive kit provides all the necessary gaskets and seals for a complete engine overhaul, guaranteeing a perfect fit and reliable sealing. Manufactured from high-quality steel and other durable materials, our gasket kits are designed to withstand the demanding conditions of heavy-duty machinery, preventing leaks and maintaining consistent engine compression.

Product Specifications

Part Number: 6151-K1-3000

Engine Model: Komatsu S6D125

Material: High-grade Steel, Asbestos-Free Gasket Material, Silicone, Rubber, etc.

Kit Contents: Complete set of cylinder head gaskets, manifold gaskets, oil pan gaskets, valve cover gaskets, front and rear crankshaft seals, valve stem seals, O-rings, and other necessary seals for a full engine overhaul.

Durability: Engineered for extreme temperatures and pressures.

Precision: Manufactured to OEM specifications for a perfect fit.

Key Advantages & Applications

Our Steel Komatsu S6D125 Engine Full Overhaul Gasket Kit offers unparalleled advantages for maintaining your heavy equipment:

Superior Sealing Performance: Prevents oil leaks, coolant leaks, and compression loss, ensuring the engine operates efficiently.

Extended Engine Lifespan: A complete overhaul with high-quality gaskets restores engine integrity, significantly extending its operational life.

Cost-Effective Maintenance: Investing in a full gasket kit for an overhaul is more economical in the long run compared to frequent repairs due to minor leaks or failures.

OEM Standard Quality: Our kits meet or exceed original equipment manufacturer specifications, guaranteeing reliability and compatibility.

Reduced Downtime: With all necessary components in one kit, maintenance is streamlined, minimizing equipment downtime.

This gasket kit is specifically designed for Komatsu S6D125 engines, commonly found in a wide range of heavy-duty machinery, including:

Komatsu Excavators (e.g., PC300, PC400 series)

Komatsu Wheel Loaders (e.g., WA400, WA500 series)

Komatsu Bulldozers (e.g., D85, D155 series)

Komatsu Graders

Other heavy-duty industrial and construction equipment powered by the Komatsu S6D125 engine.

Application Scenarios & Case Studies

The Komatsu S6D125 engine, and by extension, our gasket kit, is critical for various demanding applications:

Construction Sites: Excavators and bulldozers with S6D125 engines are workhorses in foundation digging, material handling, and site preparation. A robust engine, supported by reliable gaskets, ensures uninterrupted operation in harsh, dusty environments.

Case Study: A large construction firm experienced frequent oil leaks in their PC400 excavators, leading to significant downtime. After replacing the old gaskets with our 6151-K1-3000 kit during an overhaul, the leaks ceased entirely, and engine performance improved, reducing operational costs by 15% over six months.

Mining Operations: Wheel loaders and dump trucks powered by S6D125 engines operate continuously in mines, moving massive quantities of ore and overburden. The extreme temperatures and vibrations in mining demand durable engine components.

Case Study: A remote mining site was facing issues with engine overheating in their WA500 loaders due to faulty head gaskets. Our full overhaul kit provided the necessary seals to restore proper cooling and compression, ensuring the equipment could withstand the intense workload of 24/7 mining operations.

Infrastructure Projects: Graders and compactors utilize these engines for road construction and large-scale land leveling. These applications require consistent power output and minimal environmental impact from leaks.

Case Study: During a major highway expansion, a fleet of D85 bulldozers required engine refurbishment. Using our overhaul kits, the project team was able to quickly and effectively rebuild their engines, ensuring their equipment met tight project deadlines and strict environmental regulations regarding fluid containment.

Related & Similar Products

Beyond the Komatsu S6D125 full overhaul gasket kit, we also offer a range of related and similar products to support various engine models and maintenance needs:

Partial Gasket Kits: For specific repair needs (e.g., top-end gasket kits for cylinder head repairs).

Applicable for: Komatsu S6D105, S6D110, SAA6D140 engines, and various Cummins, Caterpillar, and Volvo engines where only specific sections of the engine require new seals.

Individual Gaskets and Seals: Available for targeted replacements, such as individual head gaskets, oil pan gaskets, or valve stem seals.

Applicable for: Any engine model requiring replacement of a single, damaged gasket without needing a full kit.

Engine Bearing Kits: Main bearings, connecting rod bearings, and thrust washers for complete engine bottom-end overhauls.

Applicable for: Komatsu, Cummins, Caterpillar engines commonly found in excavators, loaders, and generators.

Engine Valve Train Components: Valves, valve guides, valve springs, and rocker arms.

Applicable for: Various heavy equipment engines requiring cylinder head maintenance.

Piston & Liner Kits: For complete cylinder rebuilds.

Applicable for: Engines undergoing significant wear and tear, needing a full top-end and bottom-end rebuild.

Common Installation & Maintenance Issues and Solutions

Proper installation and ongoing maintenance are crucial for the longevity of your engine gaskets. Here are common issues and their solutions:

Issue: Gasket Leaks Post-Installation.

Solution: This often indicates improper torque sequence or insufficient surface preparation. Always follow the manufacturer's torque specifications and sequence precisely. Ensure mating surfaces are thoroughly cleaned, free of old gasket material, scratches, or corrosion. Consider using a surface flatness gauge to check for warpage.

Issue: Premature Gasket Failure (e.g., Head Gasket Blowout).

Solution: Overheating is a primary cause. Check the cooling system for blockages, faulty thermostats, or failing water pumps. Incorrect fuel/air mixture or ignition timing can also contribute to excessive combustion temperatures. Ensure the engine is operating within its designed thermal parameters.

Issue: Incorrect Gasket Material or Type Used.

Solution: Always use the correct gasket kit (like our 6151-K1-3000 for Komatsu S6D125) that matches your engine model. Using an incorrect type (e.g., paper gasket where a multi-layer steel gasket is required) will lead to rapid failure. Verify part numbers and consult engine manuals.

Issue: Damaged Gaskets During Installation.

Solution: Handle gaskets with extreme care. Avoid bending, creasing, or tearing them. Ensure all sharp edges on the engine block or cylinder head are protected during installation. Lubricate appropriate seals with engine oil or assembly lube where specified.

Issue: Reuse of Old Gaskets.

Solution: NEVER reuse gaskets, especially critical ones like head gaskets. Gaskets are designed to deform and seal once. Reusing them significantly increases the risk of leaks and catastrophic engine failure. Always use new gaskets during any engine repair or overhaul.