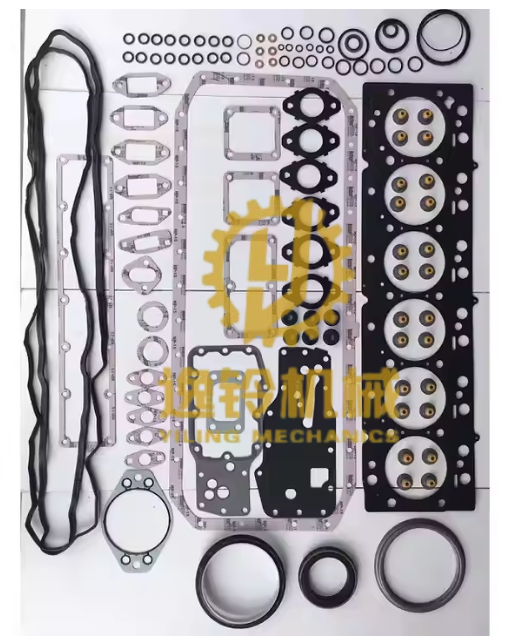

Komatsu 6D140 New Complete Gasket Set 6217-K1-9900 6217-K2-9900

Support Alibaba online purchase

Komatsu 6D140 New Complete Gasket Set (6217-K1-9900 / 6217-K2-9900)

Ensure the longevity and optimal performance of your Komatsu 6D140 engine with our brand new, complete gasket set. Specifically engineered to meet or exceed OEM specifications, this comprehensive kit provides all the necessary gaskets and seals for a complete engine overhaul, ensuring a perfect fit and leak-free operation.

Product Features & Specifications

Part Numbers: 6217-K1-9900, 6217-K2-9900

Engine Model: Komatsu 6D140

Type: Complete Gasket Set (New)

Material: High-quality, durable materials designed for extreme temperatures and pressures.

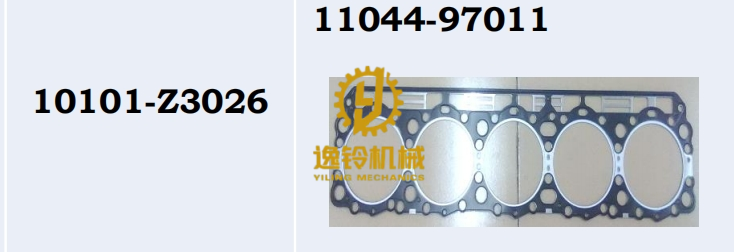

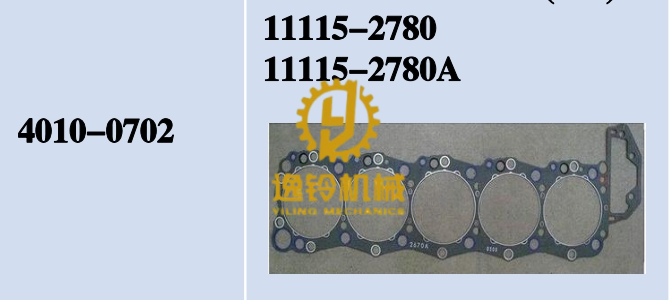

Contents: Includes head gasket, manifold gaskets, valve cover gaskets, oil pan gasket, front and rear crankshaft seals, valve stem seals, O-rings, and other necessary seals for a full engine rebuild.

Precision Engineered: Manufactured to strict tolerances for a perfect seal and fit.

Key Advantages & Selling Points

Superior Sealing Performance: Prevents oil, coolant, and combustion gas leaks, maintaining engine efficiency.

Extended Engine Lifespan: Protects vital engine components from damage due to leaks, ensuring long-term reliability.

Cost-Effective Solution: A complete set saves you time and money by providing all necessary gaskets in one package, avoiding multiple purchases.

OEM Quality and Compatibility: Manufactured to meet or exceed original equipment manufacturer standards, guaranteeing perfect fit and performance.

Reduced Downtime: Facilitates quicker and more efficient engine repairs, getting your equipment back to work faster.

Applicable Equipment

This Komatsu 6D140 Complete Gasket Set is specifically designed for Komatsu construction and industrial machinery equipped with the Komatsu 6D140 diesel engine. This includes a wide range of heavy-duty equipment such as:

Komatsu Excavators: PC650, PC750, PC800 series and similar models.

Komatsu Wheel Loaders: WA500, WA600 series and comparable models.

Komatsu Dozers: D155A, D275A series and related heavy machinery.

Komatsu Graders: GD705, GD825 series.

And other Komatsu machinery utilizing the 6D140 engine.

Application Scenarios & Case Studies

The Komatsu 6D140 engine powers a variety of heavy machinery essential for demanding applications across various industries. A complete gasket set is critical for maintaining these machines in peak condition.

Mining Operations: Large excavators (e.g., Komatsu PC750/PC800) equipped with the 6D140 engine are workhorses in open-pit mines, used for overburden removal and ore loading. A failing gasket set can lead to engine overheating and significant downtime, impacting production. Our gasket set ensures reliable engine performance in these high-stress environments.

Case Study: A mining company experienced frequent oil leaks from their PC750 excavator, leading to excessive oil consumption and environmental concerns. After installing our complete 6D140 gasket set, the leaks were eliminated, and the engine's efficiency improved, resulting in significant savings on oil and reduced environmental impact.Large-Scale Construction Projects: Wheel loaders (e.g., Komatsu WA600) and dozers (e.g., Komatsu D275A) are vital for moving vast quantities of earth, aggregate, and demolition debris on major construction sites. Engine integrity is paramount for maintaining project timelines.

Case Study: A construction firm faced a critical deadline on a highway expansion project. Their Komatsu D275A dozer began showing signs of a blown head gasket, threatening project delays. Our readily available gasket set allowed for a rapid engine repair, ensuring the dozer was back in operation within days, keeping the project on schedule.Quarrying and Aggregate Production: Equipment in quarries, such as large excavators and wheel loaders, operates continuously under dusty and abrasive conditions. Gaskets are crucial for preventing contaminants from entering the engine.

Scenario: In a busy aggregate plant, a Komatsu WA500 wheel loader's engine develops a coolant leak due to a deteriorating water pump gasket. This could lead to severe engine damage if not addressed promptly. A complete gasket set ensures that all associated seals are replaced, preventing future issues.

Related & Similar Products

Beyond the complete gasket set, we offer a wide range of Komatsu engine parts to support comprehensive maintenance and repair needs:

Individual Gaskets and Seals: Available for specific repair needs (e.g., head gasket, oil pan gasket, valve cover gasket).

Applicable for: Targeted repairs on any Komatsu engine where only a specific gasket has failed, minimizing replacement costs.Engine Rebuild Kits: Include pistons, liners, bearings, and complete gasket sets for a full engine overhaul.

Applicable for: Komatsu engines of various models (e.g., 6D125, S6D102, SAA6D107, SAA6D125, SAA6D140, SAA6D170) requiring extensive rebuilds due to wear or significant damage.Crankshafts and Camshafts: Precision-machined components for optimal engine timing and power delivery.

Applicable for: Komatsu excavators, dozers, wheel loaders, and dump trucks across various series, where these critical components are worn or damaged.Fuel System Components: Injectors, fuel pumps, and fuel lines.

Applicable for: All Komatsu diesel engines, ensuring efficient fuel delivery and combustion.Cooling System Parts: Radiators, water pumps, thermostats, and hoses.

Applicable for: Maintaining optimal operating temperatures in all Komatsu heavy equipment.

Common Installation & Maintenance Issues and Solutions

Proper installation and maintenance are crucial for the longevity of a gasket set. Here are common issues and their solutions:

Issue: Incorrect Torque Settings

Problem: Over-torquing can crush gaskets, leading to premature failure. Under-torquing can result in insufficient sealing and leaks.

Solution: Always refer to the Komatsu service manual for the precise torque specifications for each bolt. Use a calibrated torque wrench and follow the recommended tightening sequence (e.g., spiral or crisscross pattern).Issue: Improper Surface Preparation

Problem: Residual old gasket material, dirt, or nicks on mating surfaces will prevent a proper seal, leading to leaks.

Solution: Thoroughly clean all mating surfaces using a scraper or fine abrasive pad. Ensure surfaces are smooth, dry, and free of any debris or oil before installing new gaskets.Issue: Using Sealants Unnecessarily or Incorrectly

Problem: Many modern gaskets are designed to be installed dry. Using excessive or incorrect sealants can prevent the gasket from seating properly or even clog engine passages.

Solution: Only use sealants if explicitly recommended by the Komatsu service manual for specific gasket types (e.g., RTV for certain corners or non-critical interfaces). Apply sealants sparingly and evenly.Issue: Gasket Damage During Installation

Problem: Bending, tearing, or creasing a gasket during installation can compromise its integrity.

Solution: Handle gaskets with care. Ensure proper alignment before tightening bolts. For delicate gaskets, consider using alignment pins or guides.Issue: Coolant or Oil Contamination Post-Installation

Problem: Even after a new gasket set, issues can arise if the cooling system isn't properly bled or if the engine isn't filled with the correct type/amount of oil/coolant.

Solution: After installation, perform a complete flush and refill of the cooling system and oil system according to Komatsu's specifications. Ensure all air is bled from the cooling system to prevent hot spots. Monitor fluid levels and temperatures closely during the initial run-in period.