6D140 Full Gasket Kit With Cylinder Head Gasket for Komatsu Diesel Engine

Support Alibaba online purchase

6D140 Full Gasket Kit with Cylinder Head Gasket for Komatsu Diesel Engine

Product Overview

Ensure the longevity and peak performance of your Komatsu diesel engine with our premium 6D140 Full Gasket Kit, including a high-quality cylinder head gasket. This comprehensive kit provides all the necessary gaskets and seals for a complete engine overhaul or major repair, preventing leaks and maintaining optimal compression. Manufactured to meet or exceed OEM specifications, our gaskets are designed for durability and a perfect fit, guaranteeing reliable engine operation in demanding environments.

Product Specifications

Product Type: Full Gasket Kit with Cylinder Head Gasket

Engine Model: Komatsu 6D140 Diesel Engine

Material: High-grade composite materials, asbestos-free

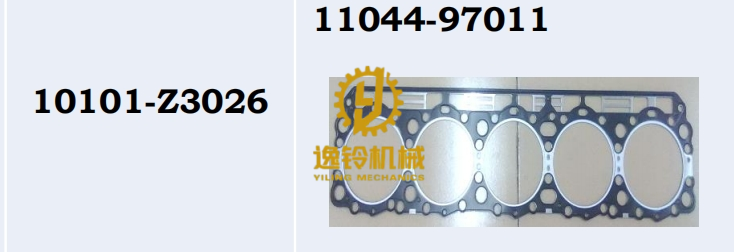

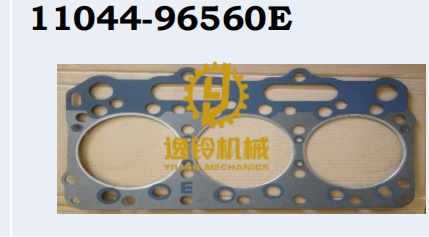

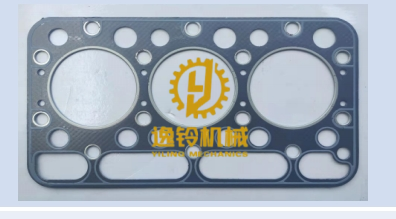

Components Included: Cylinder head gasket, intake manifold gasket, exhaust manifold gasket, valve cover gasket, oil pan gasket, front and rear crankshaft seals, valve stem seals, timing cover gasket, water pump gasket, thermostat housing gasket, and various other auxiliary gaskets and O-rings.

Compatibility: Direct replacement for OEM parts

Condition: Brand New

Key Advantages & Selling Points

✓ Complete Solution: This full kit offers all the necessary gaskets, eliminating the need to source individual components, saving time and effort.

✓ Superior Durability: Manufactured from premium, heat-resistant, and corrosion-resistant materials, ensuring a long service life even under extreme operating conditions.

✓ Precision Fit: Engineered with precision to guarantee a perfect seal, preventing oil and coolant leaks and maintaining optimal engine compression.

✓ Enhanced Performance: Restores engine efficiency and power by preventing pressure loss and ensuring proper sealing of critical engine components.

✓ Cost-Effective: A complete kit reduces overall repair costs compared to purchasing individual gaskets, offering excellent value.

Applicable Equipment

This 6D140 Full Gasket Kit is specifically designed for Komatsu diesel engines, commonly found in a wide range of heavy machinery and industrial equipment, including but not limited to:

Komatsu Excavators: PC300, PC350, PC400 Series

Komatsu Wheel Loaders: WA450, WA470 Series

Komatsu Bulldozers: D85, D155 Series

Komatsu Articulated Dump Trucks: HM300 Series

Other Komatsu Heavy Construction Equipment and Industrial Applications utilizing the 6D140 engine.

Application Scenarios & Case Studies

The Komatsu equipment powered by the 6D140 engine is a workhorse across various demanding industries. Our gasket kit is essential for maintaining these machines in peak condition.

Construction Sites: Excavators and bulldozers with the 6D140 engine are pivotal for large-scale earthmoving, foundation digging, and material handling. A worn-out gasket can lead to coolant leaks or compression loss, halting critical operations. Our gasket kit ensures these machines continue to operate efficiently, minimizing downtime.

Mining Operations: In the harsh mining environment, Komatsu equipment endures extreme stress. Wheel loaders and dump trucks are continuously moving heavy loads. A reliable cylinder head gasket is crucial to prevent overheating and maintain engine integrity. Our kit provides the necessary sealing to withstand these rigorous conditions.

Quarry Operations: Similar to mining, quarries demand robust machinery. Komatsu equipment is used for breaking, loading, and transporting rock. Maintaining a leak-free engine with our full gasket kit ensures consistent power delivery and avoids costly repairs that could impact production schedules.

Infrastructure Development: From road construction to bridge building, Komatsu machines are indispensable. Regular maintenance using quality gasket kits is vital to ensure these heavy-duty engines perform reliably, preventing unexpected breakdowns that can delay major projects.

Case Study: A large construction company experienced frequent overheating issues and coolant loss in their Komatsu PC400 excavator. Upon inspection, it was determined that the cylinder head gasket had failed. By replacing it with our 6D140 Full Gasket Kit, the engine's temperature stabilized, coolant consumption returned to normal, and the excavator resumed full operational capacity, preventing significant project delays and repair costs.

Related & Similar Products

Beyond the 6D140 full gasket kit, we offer a wide range of engine components for various Komatsu and other heavy equipment models. Here are some related products:

Komatsu S6D125 Gasket Kits: Suitable for Komatsu excavators (PC400-6, PC450-6) and wheel loaders (WA500-1).

Komatsu 4D95 Gasket Kits: Commonly used in smaller Komatsu excavators (PC60, PC70) and forklifts.

Cummins B Series Gasket Kits (4BT, 6BT): Applicable to various construction equipment, agricultural machinery, and commercial vehicles.

Cylinder Head Bolts: Essential for a complete cylinder head replacement or overhaul, compatible with Komatsu 6D140.

Engine Bearings (Main, Con Rod, Thrust): For Komatsu 6D140 and other compatible engines, crucial for crankshaft and connecting rod rotation.

Piston & Liner Kits: Available for Komatsu 6D140 and various other engine models, vital for compression and combustion.

Common Installation & Maintenance Issues and Solutions

Proper installation and ongoing maintenance are crucial for the longevity of your gasket kit and engine. Here are some common issues and their solutions:

⚠ Issue: Coolant Leakage from Cylinder Head Gasket.

Solution: This often indicates improper torqueing of cylinder head bolts or a warped cylinder head/engine block surface. Always follow the manufacturer's torque specifications and sequence precisely. Before installation, ensure cylinder head and block surfaces are thoroughly cleaned and flat. Consider having surfaces machined if significant warping is present.

⚠ Issue: Oil Leaks after Gasket Replacement.

Solution: Common causes include damaged or improperly installed oil pan gaskets, valve cover gaskets, or crankshaft seals. Ensure all mating surfaces are clean and dry before applying new gaskets. Use appropriate RTV sealant where specified by the engine manufacturer. Verify correct seal orientation and seating.

⚠ Issue: Premature Gasket Failure.

Solution: This can be due to overheating, incorrect fuel/air mixture, or using incompatible coolants/oils. Regularly monitor engine temperature, ensure cooling system is clean and functional, and use only recommended fluids. Over-tightening or under-tightening bolts can also lead to premature failure; always use a torque wrench.

⚠ Issue: Compression Loss.

Solution: If the cylinder head gasket is new, verify it was installed correctly and that the cylinder head was properly torqued. Other potential causes include damaged valve seats, worn piston rings, or incorrect valve lash. Conduct a compression test to pinpoint the affected cylinder(s) and inspect corresponding components.

Maintenance Tips: Always use genuine or high-quality aftermarket parts. During any engine repair involving gaskets, thoroughly clean all mating surfaces. Inspect components for wear, cracks, or damage. Regularly check fluid levels and temperatures. Follow recommended service intervals for engine components to prevent issues before they arise.