6D170 Engine Full Overhaul Gasket Kit 6162-K2-1302 6162-K1-1302 Compatible with Komatsu Excavator Engine Spare Parts

Support Alibaba online purchase

6D170 Engine Full Overhaul Gasket Kit - Precision Engine Restoration

Product Overview

Restore your Komatsu excavator engine to optimal performance with our premium 6D170 Engine Full Overhaul Gasket Kit. Engineered for a perfect fit and exceptional durability, this comprehensive kit, with part numbers 6162-K2-1302 and 6162-K1-1302, provides all the necessary gaskets and seals for a complete engine overhaul. Designed to meet or exceed OEM specifications, our gasket kit ensures a reliable and long-lasting repair, preventing leaks and maintaining consistent engine pressure.

Product Parameters

Part Numbers: 6162-K2-1302, 6162-K1-1302

Engine Model Compatibility: Komatsu 6D170 Engine Series

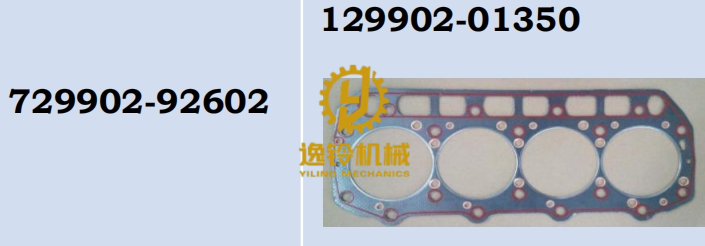

Kit Contents: Full set of gaskets, oil seals, valve stem seals, O-rings, and other necessary sealing components for a complete engine overhaul.

Material: High-quality, heat-resistant, and durable materials designed for extreme engine environments.

Standards: Manufactured to meet or exceed OEM specifications for fit, form, and function.

Packaging: Securely packaged to prevent damage during transit.

Key Advantages & Selling Points

Complete Overhaul Solution: This kit provides every gasket and seal needed for a comprehensive engine rebuild, saving you time and ensuring no critical components are missed.

OEM-Level Quality: Manufactured with precision and using premium materials, our gaskets ensure a perfect seal, preventing oil leaks, coolant leaks, and compression loss.

Enhanced Durability: Designed to withstand the rigorous conditions of heavy-duty engine operation, ensuring a longer lifespan for your engine after overhaul.

Cost-Effective Repair: A full gasket kit is a more economical solution than purchasing individual components, reducing overall repair costs.

Optimized Engine Performance: A proper seal ensures correct engine compression and lubrication, leading to improved fuel efficiency and power output.

Applicable Equipment

This 6D170 Engine Full Overhaul Gasket Kit is specifically designed for Komatsu excavators equipped with the powerful Komatsu 6D170 engine series. This includes, but is not limited to, models such as:

Komatsu PC800-8R Excavator

Komatsu PC1250-8 Excavator

Komatsu PC1250SP-8 Excavator

Komatsu PC1250LC-8 Excavator

Komatsu D375A-6 Bulldozer

And other Komatsu heavy machinery utilizing the 6D170 engine.

Application Scenarios & Case Studies

Komatsu excavators powered by the 6D170 engine are workhorses in various demanding industries. Our gasket kit is crucial for maintaining these machines in peak condition, ensuring continuous operation in critical applications:

Mining Operations: Large excavators like the PC1250 are essential for overburden removal and ore extraction in open-pit mines. A failing engine due to worn gaskets can halt production, leading to significant financial losses. Our overhaul kit ensures these machines operate reliably through continuous, heavy-duty cycles in harsh environments.

Case Study: A large mining company experienced frequent downtime with their PC1250 excavators due to oil leaks and reduced engine power. After implementing our 6D170 full overhaul gasket kits during scheduled maintenance, they reported a 15% increase in operational uptime and a noticeable improvement in fuel efficiency across their fleet.Large-Scale Construction Projects: These excavators are vital for massive earthmoving tasks, foundational work for high-rise buildings, and highway construction. Engine integrity is paramount to meet tight project deadlines.

Case Study: During the construction of a new railway line, a contractor's D375A-6 bulldozer began showing signs of head gasket failure. Timely replacement with our overhaul kit prevented catastrophic engine damage and allowed the project to stay on schedule, avoiding costly delays.Quarrying and Aggregate Production: In quarries, these machines are used for breaking and moving large rock formations. The dusty and abrasive environment places immense stress on engine components, making reliable sealing crucial.

Case Study: A quarry operator noted higher oil consumption and exhaust smoke from their PC800-8R. A preventative engine overhaul using our gasket kit restored engine seals, significantly reducing oil consumption and ensuring compliance with environmental regulations.

Related Products

To complement your engine maintenance needs, consider these related products, also compatible with various heavy machinery:

Engine Bearing Sets (Main & Conrod): Essential for reducing friction and supporting rotating components.

Applicable Equipment: Komatsu, Caterpillar, Volvo, Hitachi excavators and bulldozers.Piston & Liner Kits: Crucial for maintaining optimal compression and combustion efficiency.

Applicable Equipment: Komatsu, Cummins, Isuzu, Yanmar engines in various heavy equipment.Engine Oil Pumps: Ensures consistent lubrication throughout the engine, preventing premature wear.

Applicable Equipment: A wide range of construction and mining machinery with internal combustion engines.Turbochargers: Boosts engine power and efficiency.

Applicable Equipment: Diesel engines in excavators, loaders, and trucks, including Komatsu, Cummins, and John Deere.

Common Installation & Maintenance Issues and Solutions

Issue: Gasket Leaks Post-Installation.

Problem: Improper surface preparation (e.g., old gasket residue, scratches, dirt) or incorrect torque specifications.

Solution: Thoroughly clean all mating surfaces, ensuring they are smooth and free of debris. Always use a torque wrench and follow the manufacturer's recommended torque sequence and specifications for all bolts.Issue: Premature Gasket Failure.

Problem: Over-torquing, under-torquing, using the wrong type of sealant (if any), or engine overheating.

Solution: Adhere strictly to torque specs. Use sealant sparingly only where specified by the engine manual. Address any underlying engine cooling system issues to prevent overheating, which can compromise gasket integrity.Issue: Misalignment of Gaskets.

Problem: Gaskets not correctly seated during assembly, leading to crimping or tearing.

Solution: Take your time during installation. Use alignment pins or guide studs where available. Ensure the gasket is perfectly aligned before tightening any fasteners.Issue: Incomplete Kit or Missing Components.

Problem: Receiving a kit that doesn't contain all necessary parts for a full overhaul.

Solution: Before starting the overhaul, meticulously cross-reference the kit contents with the engine's service manual or parts list to ensure all required gaskets and seals are present. Purchase from reputable suppliers who guarantee comprehensive kits.