engine gaskets KOMATSU 6D170,Engine Head Gasket, Engine Gasket Kit, Manifold Gasket, Head cover gasket, Gasket Oil pan, Seals,

Support Alibaba online purchase

Premium Engine Gaskets for KOMATSU 6D170 Engines

Product Overview

Ensure the optimal performance and longevity of your KOMATSU 6D170 engine with our comprehensive range of high-quality engine gaskets and seals. Designed for a perfect fit and superior sealing, our gaskets prevent leaks, maintain proper compression, and protect vital engine components from contaminants. From complete engine gasket kits to individual components like head gaskets, manifold gaskets, and oil pan gaskets, we provide reliable solutions for all your sealing needs.

Product Parameters

Material: High-grade composite materials, graphite, steel, and rubber, engineered for extreme temperatures and pressures.

Compatibility: Specifically engineered for KOMATSU 6D170 series engines.

Components Available:

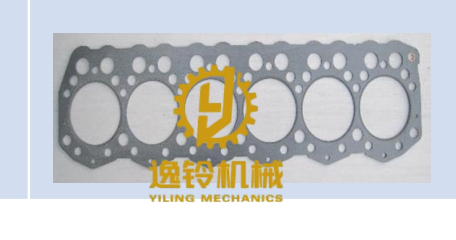

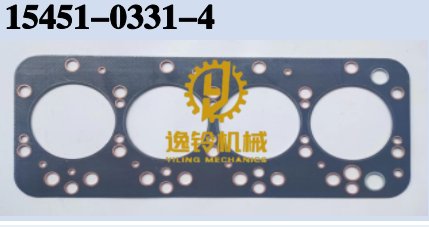

Engine Head Gasket

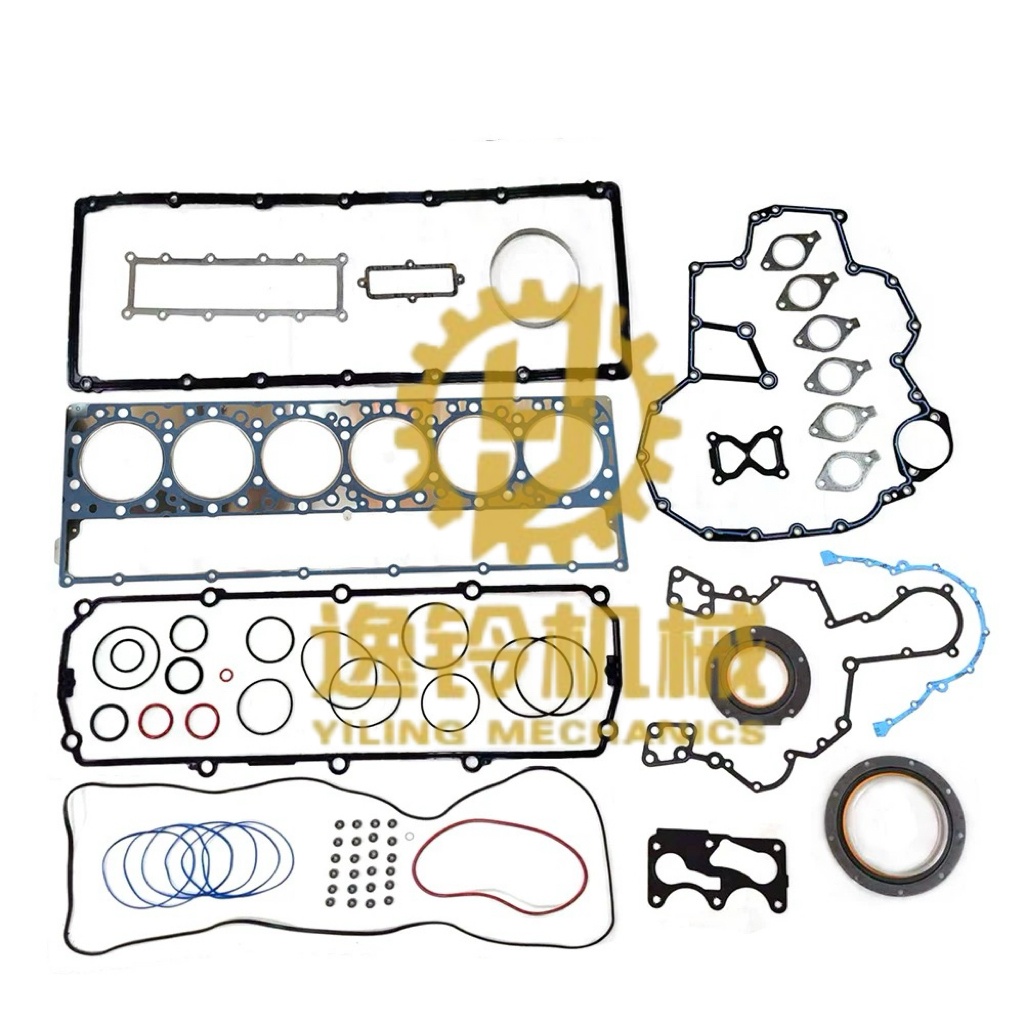

Engine Gasket Kit (Full set)

Manifold Gasket (Exhaust and Intake)

Head Cover Gasket

Gasket Oil Pan

Various Seals (Valve stem seals, crankshaft seals, camshaft seals, etc.)

Standards: Manufactured to meet or exceed OEM specifications for fit, form, and function.

Key Advantages and Selling Points

Superior Sealing Performance: Precision-engineered to prevent leaks of oil, coolant, and combustion gases, ensuring optimal engine efficiency.

Durable Construction: Made from robust materials that withstand high temperatures, pressure, and corrosive environments, extending engine life.

Exact Fit: Designed to OEM specifications for seamless installation and perfect alignment with existing engine components.

Enhanced Engine Reliability: Reduces the risk of engine damage due to fluid leaks or loss of compression, improving overall reliability and reducing downtime.

Cost-Effective Maintenance: High-quality gaskets reduce the frequency of repairs and replacements, leading to significant long-term savings.

Applicable Equipment and Application Scenarios

Our KOMATSU 6D170 engine gaskets are essential components for a wide range of heavy machinery and equipment powered by the KOMATSU 6D170 engine. These include, but are not limited to:

Komatsu Excavators: Such as the PC600-7, PC650-7, PC750-7, and PC800-7 models. These excavators are widely used in large-scale construction, mining, and demolition projects, where reliable engine performance is critical for efficient operation.

Komatsu Wheel Loaders: Including models like the WA500-3 and WA600-3. These machines are vital for material handling, loading, and stockpiling in construction sites, quarries, and industrial facilities, demanding robust engine sealing to withstand continuous heavy-duty cycles.

Komatsu Dozers: Such as the D155A-5 and D375A-5. Dozers are fundamental for earthmoving, grading, and land clearing in various applications, from road construction to agricultural land development. The integrity of engine gaskets ensures consistent power delivery and prevents overheating in these demanding environments.

Komatsu Dump Trucks: For example, the HD465-7 and HD605-7 models. These trucks operate in challenging conditions, transporting heavy loads in mining operations and large construction sites. Reliable gaskets are crucial for maintaining engine performance and preventing costly downtime in remote and demanding locations.

Case Study: Mining Operation in South America

A large-scale mining operation in South America relies heavily on a fleet of Komatsu PC800-7 excavators and HD605-7 dump trucks, all powered by KOMATSU 6D170 engines. Facing frequent engine overheating and oil leaks due to generic, low-quality gaskets, their operational efficiency was significantly impacted. After switching to our premium engine gaskets, the mining company reported a drastic reduction in unscheduled downtime, extended engine life, and improved fuel efficiency across their fleet. The superior sealing capabilities of our gaskets ensured consistent engine temperature and pressure, crucial for maintaining peak performance in the harsh mining environment.

Related Products

Beyond our core KOMATSU 6D170 gasket range, we also offer a variety of related sealing products for various heavy equipment engines:

Cylinder Head Gaskets for Caterpillar C15 Engines: Ideal for Caterpillar trucks (e.g., Peterbilt, Kenworth) and heavy equipment, ensuring optimal compression and preventing coolant/oil mixing.

Complete Gasket Sets for Cummins N14 Engines: Crucial for heavy-duty trucks (e.g., Freightliner, International) and industrial power generation, offering a full suite of seals for comprehensive engine overhaul.

Exhaust Manifold Gaskets for Detroit Diesel Series 60 Engines: Designed for buses and commercial trucks, these gaskets withstand high exhaust temperatures, preventing leaks and maintaining emission control.

Oil Cooler Gaskets and Seals for John Deere PowerTech Engines: Essential for agricultural machinery (tractors, harvesters) and construction equipment, ensuring proper oil cooling and preventing costly leaks.

Common Installation & Maintenance Issues and Solutions

Issue: Improper Torque during Installation

Problem: Overtightening or undertightening bolts can lead to gasket failure, leaks, or even damage to engine components.

Solution: Always follow the manufacturer's specified torque sequence and values. Use a calibrated torque wrench and tighten fasteners in stages to ensure even compression across the gasket surface.

Issue: Dirty or Damaged Mating Surfaces

Problem: Residual dirt, old gasket material, or scratches on mating surfaces prevent a proper seal, leading to leaks.

Solution: Thoroughly clean and inspect all mating surfaces before installing a new gasket. Use a gasket scraper or fine abrasive pad to remove old material and ensure surfaces are smooth and free of imperfections.

Issue: Using Incorrect Gasket Type or Material

Problem: Substituting a gasket not designed for the specific application or using inferior materials can lead to premature failure due to incompatible temperature or pressure requirements.

Solution: Always use gaskets specifically designed for your engine model and application. Our KOMATSU 6D170 gaskets are engineered to meet OEM specifications for optimal performance and durability.

Issue: Coolant or Oil Contamination

Problem: Contaminated fluids can degrade gasket materials over time, leading to leaks and engine damage.

Solution: Regularly check and maintain fluid levels and quality. Address any underlying issues causing contamination to prevent premature gasket wear.