Gasket Kit 6D170-5 SAA6D170E SAA6D170E-5A Top Repair Kit 6240-11-1810 Suitable for Komatsu Engine Repair Parts Set

Support Alibaba online purchase

Gasket Kit 6D170-5 SAA6D170E SAA6D170E-5A Top Repair Kit 6240-11-1810

Essential Repair Parts Set for Komatsu Engines

Product Overview

The Gasket Kit 6D170-5 SAA6D170E SAA6D170E-5A Top Repair Kit 6240-11-1810 is a comprehensive and high-quality set of repair parts designed specifically for Komatsu engines. This full gasket set is crucial for performing top-end engine overhauls and repairs, ensuring a precise and reliable seal for critical engine components. Manufactured to OEM specifications, this kit guarantees optimal performance and extends the lifespan of your heavy machinery.

Product Parameters & Key Features

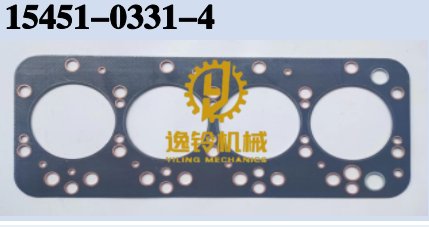

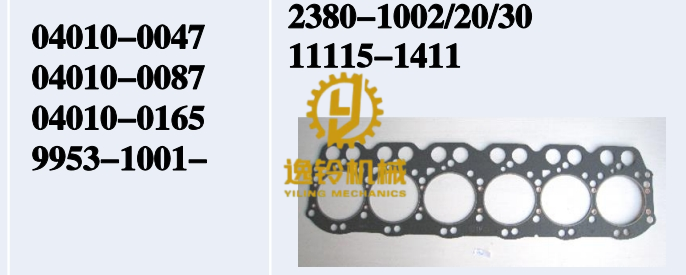

Part Number: 6240-11-1810

Engine Models: Specifically designed for Komatsu 6D170, S6D170, SAA6D170E, and SAA6D170E-5A series engines.

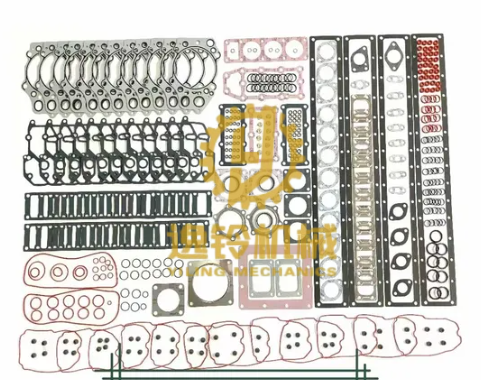

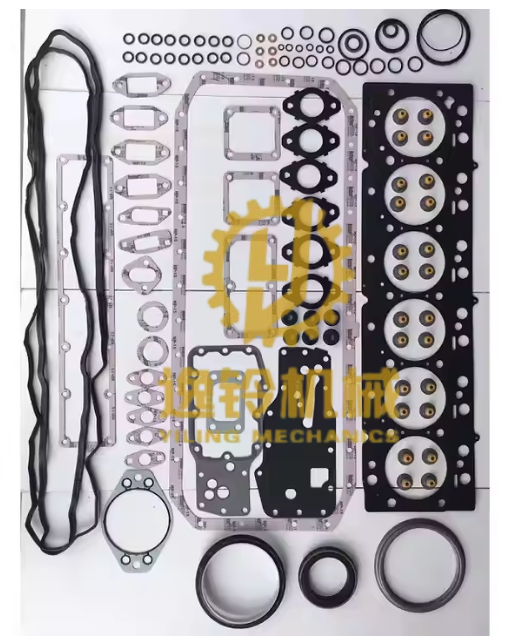

Kit Contents: Includes a full range of gaskets and seals for the top-end overhaul, such as Head Gaskets, Crankshaft Oil Seals (front & rear), Valve Stem Oil Seals, Oil Pan Gasket Set, Valve Cover Gasket, Exhaust Manifold Gasket, Intake Manifold Gasket, Water Pump Gasket, Copper Washer Gasket Set, Timing Cover Gasket, Engine Rubber Set, and various other crucial gaskets.

Precision Fit: Manufactured to precise OEM (Original Equipment Manufacturer) dimensions for seamless installation and perfect sealing.

Quality Materials: Made from durable, high-quality materials to withstand the extreme conditions within heavy-duty engine operations, ensuring leak-free performance and longevity.

Warranty: Typically comes with a 6-month to 1-year warranty, offering peace of mind regarding its quality and durability.

Applicable Equipment & Selling Points

This gasket kit is universally suitable for various Komatsu heavy machinery equipped with the 6D170, S6D170, SAA6D170E, and SAA6D170E-5A engines. Its key selling points lie in its ability to restore engine integrity and prevent costly downtime.

Applicable Equipment:

Komatsu Excavators: PC1000-1, PC1250-8, PC1250-11, and other models utilizing the specified engines.

Komatsu Wheel Loaders: WA600-3LK, WA600-6, WA600-8.

Komatsu Dump Trucks: HD465-7, HD605-7.

Komatsu Crawler Dozers: D375A-6.

General heavy machinery including forklifts, trucks, loaders, and bulldozers powered by Komatsu 170-series engines.

Advantages:

Enhanced Performance: Restores engine compression and prevents fluid leaks, leading to improved engine efficiency and power output.

Cost-Effective Repair: Provides a comprehensive solution for top-end repairs, reducing the need for individual part sourcing and minimizing repair costs.

Extended Engine Life: By ensuring proper sealing and protection of internal components, the kit contributes significantly to the longevity of the engine.

Reliability: Manufactured to meet or exceed OEM standards, offering dependable performance in demanding operational environments.

Application Scenarios & Case Analysis

The Komatsu SAA6D170E and its variants are workhorse engines widely utilized in the most demanding sectors. This gasket kit is indispensable for maintaining these machines in peak condition across various critical applications:

Typical Application Scenarios:

Construction Sites: Powering large excavators, dozers, and wheel loaders for earthmoving, demolition, and material handling in civil engineering projects.

Mining Operations: Essential for heavy-duty dump trucks and large excavators used in open-pit and underground mines, where continuous operation in harsh conditions is vital.

Quarry & Aggregate Production: Maintaining crushing and screening equipment, as well as large loaders and excavators for extracting and processing aggregates.

Industrial & Infrastructure Projects: Supporting large-scale industrial machinery and equipment used in port operations, dam construction, and other heavy infrastructure development.

Case Analysis: Ensuring Uptime in Mining

Consider a large-scale iron ore mining operation where Komatsu HD605-7 dump trucks, powered by SAA6D170E engines, run almost continuously to transport thousands of tons of ore daily. Engine reliability is paramount; any downtime translates directly to significant financial losses. If a cylinder head gasket fails due to prolonged stress, high temperatures, or material degradation, it can lead to coolant leaks, oil contamination, or loss of compression.

By having the Gasket Kit 6240-11-1810 readily available, maintenance teams can quickly replace the affected gaskets during scheduled maintenance or emergent repairs. The precision fit and high-quality materials of this top repair kit ensure a robust seal, preventing further damage and restoring the engine to its optimal operating parameters. This proactive approach minimizes unscheduled downtime, maintains operational efficiency, and protects the substantial investment in heavy mining equipment. The kit's comprehensive nature means all necessary sealing components are present, streamlining the repair process and ensuring a thorough overhaul.

Related Similar Products

In addition to the top repair gasket kit, maintaining Komatsu 6D170/SAA6D170E engines often requires a range of other critical repair parts. Here are some related products that are frequently needed for comprehensive engine maintenance and overhauls:

Cylinder Liner & Piston Sets: Essential for restoring cylinder compression and combustion efficiency. Applicable for various Komatsu excavators, loaders, and dump trucks. (e.g., Cylinder Liner 6162-25-2210, Piston with pin 6162-33-2120)

Main & Rod Bearing Sets: Crucial for crankshaft and connecting rod support, reducing friction and ensuring smooth engine rotation. Used in all Komatsu heavy machinery with 170-series engines. (e.g., Main Bearing Set 6162-23-8000, Rod Bearing Set 6162-33-3041)

Crankshaft & Camshaft: Core components for engine timing and power transmission, necessary for major engine rebuilds. Applicable to all equipment using these Komatsu engines. (e.g., Crankshaft 6162-33-1202, Camshaft 6162-43-1101)

Engine Valves & Valve Train Components: Including intake and exhaust valves, valve springs, and valve seats, vital for proper air-fuel mixture control. Used across the range of Komatsu excavators and haul trucks. (e.g., Exhaust Valve 6164-41-4211, Intake Valve 6162-43-4111)

Oil & Water Pumps: Critical for lubrication and cooling systems, preventing overheating and component wear. Essential for all Komatsu machinery with 170-series engines. (e.g., Oil Pump 6162-53-1012, Water Pump 6162-63-1016)

Fuel Injectors & Nozzles: Responsible for precise fuel delivery, impacting engine performance and fuel efficiency. Applicable to all Komatsu equipment. (e.g., Fuel Injector Nozzle 6162-13-3320)

Common Installation & Maintenance Issues and Solutions

Proper installation and ongoing maintenance are crucial for the longevity and performance of Komatsu engine gaskets. Addressing common issues can prevent premature failure and ensure optimal engine operation.

1. Improper Surface Preparation:

Problem: Residual old gasket material, corrosion, or surface imperfections on mating surfaces (e.g., cylinder head, engine block) can prevent a proper seal, leading to leaks.

Solution: Thoroughly clean all mating surfaces before installing new gaskets. Use a plastic scraper or fine abrasive pad (avoiding excessive abrasion that can alter flatness) to remove old material. Ensure surfaces are perfectly flat, clean, and dry.

2. Incorrect Torque Specifications:

Problem: Over-tightening can crush or damage the gasket, leading to premature failure. Under-tightening can result in an inadequate seal and leaks.

Solution: Always follow the manufacturer's specified torque sequence and values for cylinder head bolts and other critical fasteners. Use a calibrated torque wrench and tighten bolts in a phased, crisscross pattern to ensure even pressure distribution.

3. Using the Wrong Gasket Type or Material:

Problem: Gaskets are designed for specific applications and temperature/pressure ranges. Using an incorrect or substandard gasket will lead to failure.

Solution: Always use genuine Komatsu parts or high-quality aftermarket equivalents like the 6240-11-1810 kit, which is engineered for these specific engines. Verify part numbers and ensure compatibility before installation.

4. Damage During Installation:

Problem: Kinking, bending, or tearing gaskets during handling or installation can compromise their sealing ability.

Solution: Handle gaskets carefully. Ensure they are aligned correctly before seating and tightening. Apply a thin layer of sealant (if recommended by the manufacturer, but not typically needed for head gaskets) to aid in positioning and initial seal, but avoid excessive sealant.

5. Overheating Issues:

Problem: Persistent engine overheating can severely degrade gasket materials, leading to warping and failure.

Solution: Address the root cause of overheating promptly (e.g., cooling system issues, thermostat failure, clogged radiator). Regular monitoring of engine temperature and coolant levels is essential for preventive maintenance.

General Maintenance Tip: Regular engine health checks, including monitoring for fluid leaks (oil, coolant), unusual noises, or performance drops, can help identify gasket issues early. Always refer to the specific Komatsu service manual for detailed, model-specific installation procedures and maintenance schedules.