Gasket Kit 6D170-3 SA6D170E SA6D170E-3A-7 Top Repair Kit 6241-K1-9900 Suitable for Komatsu Engine Repair Set

Support Alibaba online purchase

Product Details

Gasket Kit 6D170-3 SA6D170E SA6D170E-3A-7 Top Repair Kit 6241-K1-9900

The Gasket Kit 6D170-3 SA6D170E SA6D170E-3A-7 Top Repair Kit 6241-K1-9900 is a high-quality, comprehensive solution specifically designed for Komatsu heavy machinery engines. This top repair kit is essential for maintaining engine integrity and performance, preventing costly downtime due to leaks and wear.

Product Parameters & Advantages

Part Number: 6241-K1-9900

Type: Upper Cylinder Head Gasket Kit / Full Gasket Kit

Typical Contents: Includes essential components such as:

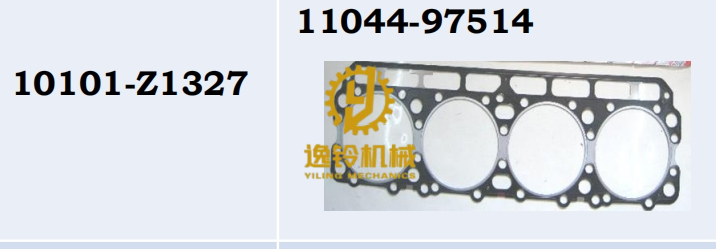

Cylinder Head Gaskets

Crankshaft Oil Seals (Front & Rear)

Valve Stem Oil Seals

Oil Pan Gasket Set

Valve Cover Gasket

Exhaust Manifold Gaskets

Intake Manifold Gaskets

Water Pump Gasket

Copper Washer Gasket Set

Timing Cover Gasket

Engine Rubber Set

Other auxiliary gaskets and seals

Material: Constructed from durable, high-quality metal, plastic, and PPC compounds engineered to withstand extreme temperatures and pressures.

Weight: Approximately 8 kg (varies slightly by specific components).

Warranty: Comes with a 1-year manufacturer's warranty, ensuring reliability and peace of mind.

Quality Assurance: Designed to meet or exceed OEM (Original Equipment Manufacturer) quality specifications, guaranteeing a perfect fit and optimal performance.

Durability: Manufactured with robust materials that resist wear, corrosion, and temperature fluctuations, ensuring long-lasting reliability in demanding operational environments.

Comprehensive Solution: Provides a complete set of gaskets necessary for a thorough top-end engine repair, saving time and simplifying the procurement process.

High Compatibility: Precisely engineered for specific Komatsu engine models, reducing maintenance issues and enhancing machinery longevity.

Applicable Equipment and Application Scenarios

This Gasket Kit is specifically suitable for a range of Komatsu engines and heavy machinery, ensuring reliable operation in various demanding environments:

Komatsu Engine Models:

6D170 Series

SA6D170E Series (including SA6D170E-3, SA6D170E-3A-7)

SAA6D170E Series (including SAA6D170E-3, SAA6D170E-3F-8)

Komatsu Heavy Machinery:

Wheel Loaders: Specifically the WA600-3LK model, which is widely used in construction, mining, and aggregate handling for loading materials onto trucks or into hoppers.

Excavators: Such as the PC1000-1, commonly deployed in large-scale earthmoving, demolition, and mining operations where robust digging and lifting capabilities are crucial.

Bulldozers: Including models like the D355C-3, essential for land clearing, grading, and pushing large quantities of soil, sand, or debris in construction and mining.

Other Applications: Also compatible with various Komatsu Forklifts, Trucks, and Buses utilizing the specified engine series, operating in logistics, transportation, and public services.

Case Study: A large mining operation utilizing Komatsu haul trucks (often powered by 6D170 series engines) experienced a critical issue with dropping coolant pressure in one of its engines. Thanks to proactive monitoring and the availability of high-quality repair kits, the failing head gasket was identified early. This swift action prevented complete engine failure and significant downtime, saving the operation an estimated US$250,000 in replacement costs and lost productivity. This highlights the importance of using reliable gasket kits for preventive maintenance and timely repairs in critical applications.

Related & Similar Products

Beyond the 6241-K1-9900 Top Repair Kit, other related gasket sets are vital for comprehensive Komatsu engine maintenance:

6241-K2-9900 Block Gasket Set: Essential for maintaining the lower engine block integrity of 6D170 series engines, often required during full engine overhauls.

6241-K6-9900 Water Pump Gasket Set: Crucial for ensuring the proper sealing and efficient operation of the water pump, preventing coolant leaks that can lead to overheating in 6D170 and PC1250-7 applications.

Other Komatsu Engine Gasket Kits:

S6D95 / 6D95L Engine Full Gasket Kits: Applicable for Komatsu Excavators (e.g., PC120-3, PC200-5, PC200-6, PC220-6, PC230-6, PC240-6) and Yanmar Forklifts (e.g., FD33N-FD80E).

S6D140 / SA6D140E Overhaul Gasket Kits: Used in larger Komatsu machinery such as Excavators PC750-6, PC650-3, PC800-6.

4D94 Engine Gasket Kits: Designed for various Komatsu excavators and dozers, ensuring the reliability of smaller to medium-sized equipment.

General Overhaul Rebuild Kits: Comprehensive kits that often include not only gaskets but also pistons, rings, liners, bearings, and valves for a complete engine overhaul, catering to a broader range of Komatsu engine models.

Installation & Maintenance: Common Issues & Solutions

Proper installation and regular maintenance are paramount to maximize the lifespan and effectiveness of your gasket kit. Here are common issues and their solutions:

Common Issues:

Fluid Leaks: Visible coolant, oil, or fuel leaks are primary indicators of gasket seal failure.

Overheating: Often caused by coolant leakage through a damaged gasket, leading to inefficient engine cooling.

Loss of Power/Abnormal Noises: Can signal compression loss through failed gaskets, affecting engine performance and producing knocking sounds.

Oil Contamination: Coolant mixing with engine oil due to a blown head gasket, leading to bearing damage or hydrolocking.

Premature Wear: Caused by sub-par coolant flow, filthy operating conditions, or low vehicle speed resulting in excessive engine temperatures.

Solutions & Prevention:

Thorough Surface Preparation: Before installing a new gasket, always ensure that mating surfaces are meticulously cleaned and free from old gasket material, debris, or corrosion.

Correct Tightening Torque: Follow the manufacturer's specifications for bolt tightening torque. Over-tightening or under-tightening can lead to premature gasket failure.

Never Reuse Gaskets: Gaskets are designed for single use. Reusing them compromises the seal and significantly increases the risk of leaks and subsequent damage.

Qualified Installation: For heavy machinery engines, installation should ideally be performed by qualified professionals or Komatsu-certified technicians to ensure proper procedure and fitment.

Regular Inspections: Periodically inspect gaskets for any signs of wear, cracking, deformation, or visible fluid leaks. Early detection can prevent more extensive and costly repairs.

Maintain Proper Fluid Levels: Regularly check and maintain optimal levels of engine oil and coolant. Ensure the use of correct fluid types as recommended by Komatsu.

Cooling System Health: Regularly inspect and clean the radiator, and ensure the thermostat and water pump are in good working condition to prevent overheating.

Filter Replacement: Replace fuel and oil filters according to the maintenance schedule to prevent contamination that can impact engine performance and gasket integrity.