2TNE68 2D68E Full Overhaul Head Gasket Kit For Yanmar Engine TB108 A2C Excavator

Support Alibaba online purchase

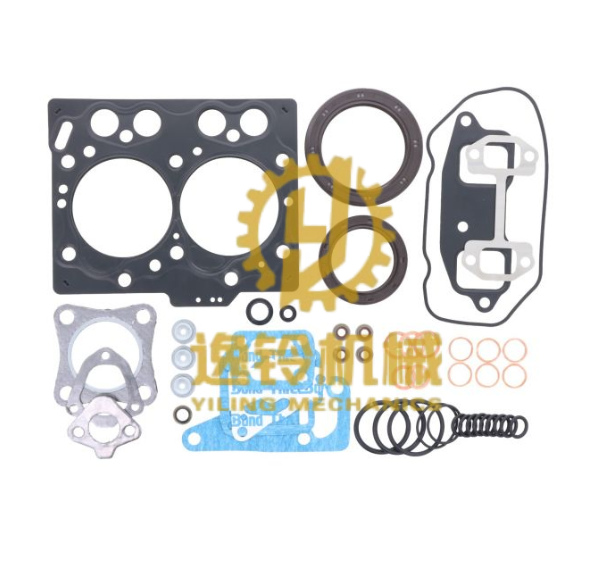

2TNE68 2D68E Full Overhaul Head Gasket Kit for Yanmar Engine TB108 A2C Excavator

Product Overview

Ensure the peak performance and longevity of your Yanmar and Komatsu engines with our high-quality 2TNE68 2D68E Full Overhaul Head Gasket Kit. Specifically engineered for a precise fit, this comprehensive kit provides all the essential gaskets and seals required for a complete engine overhaul, restoring your equipment's reliability and efficiency.

Key Product Features & Benefits

✓ Complete Overhaul Solution: Includes cylinder head gasket, intake manifold gasket, exhaust manifold gasket, valve cover gasket, valve stem seals, crankshaft front oil seal, crankshaft rear oil seal, timing case gasket, oil sump gasket, and intake manifold collector gasket.

✓ Premium Material Quality: Crafted from first-class materials, predominantly high-grade graphite, ensuring enhanced durability, excellent sealing properties, and extended service life under demanding conditions.

✓ Precision Engineering: Designed for an exact fit, preventing leaks and ensuring optimal compression, which is crucial for maintaining engine power and fuel efficiency.

✓ Easy Installation: While professional installation is recommended, the kit's design facilitates a straightforward replacement process for experienced mechanics.

✓ Enhanced Engine Performance: A proper seal restores engine compression and prevents fluid mixing, leading to improved overall performance and reliability.

Product Parameters

| Component | Description |

|---|---|

| Kit Type | Full Overhaul Head Gasket Kit |

| Material | High-Quality Graphite & Rubber-Metal Composites |

| Part Numbers | Equivalent to OEM 2TNE68, 2D68E Gasket Kits |

| Contents | Cylinder Head Gasket, Manifold Gaskets (Intake/Exhaust), Valve Cover Gasket, Valve Stem Seals, Crankshaft Oil Seals (Front/Rear), Timing Case Gasket, Oil Sump Gasket. |

Applicable Engine Specifications (Yanmar 2TNE68 / Komatsu 2D68E)

Engine Type: Vertical In-line, 2-Cylinder, 4-Cycle, Water-cooled Diesel Engine (OHV)

Displacement: Approx. 0.523 - 0.57 Liters (31.9 cu in)

Bore x Stroke: 68 mm x 72 mm (2.67 in x 2.8 in)

Compression Ratio: 23:1

Power Output: Typically 9-13 hp (6.7-9.6 kW) depending on application and RPM

Cooling System: Radiator Cooled

Fuel System: Diesel, Indirect Injected

Applicable Equipment and Application Scenarios

This full overhaul head gasket kit is primarily designed for:

Yanmar Engine Models: 2TNE68, 2D68E (and various sub-models like 2TNE68-BL, 2TNE68-DB, 2TNE68C-BG, etc.)

Komatsu Engine Models: 2D68E (and sub-models like 2D68E-3A)

Excavators: Yanmar TB108 A2C, Takeuchi TB007, Takeuchi TB108, Yanmar B08-3, Yanmar SV08, Yanmar VIO10, Komatsu PC03-2, Komatsu PC08UU-1-A, Komatsu PC09-1, Komatsu PC10UU, Daewoo/Doosan Solar 007, Solar 010, Kobelco SK09SR, New Holland E9SR.

Other Machinery: Mini cars (Bellier, Chatenet, JDM, Microcar), compact utility equipment, small tractors, rice harvesters, small generators, and various industrial equipment utilizing the 2TNE68/2D68E engine series.

Application Scenarios & Case Analysis:

Engines like the Yanmar 2TNE68/2D68E are workhorses in various compact machinery due to their efficiency and reliability. The TB108 A2C excavator and similar mini excavators are vital for:

Construction & Landscaping: Ideal for trenching, digging foundations, grading, and demolition in confined spaces. Their compact size makes them perfect for residential projects, urban construction sites, and intricate landscaping tasks where larger machinery cannot operate. For instance, a TB108 A2C might be used to dig trenches for utility lines in a densely populated area without disrupting surrounding infrastructure significantly.

Agricultural Use: Utilized in smaller farms for tasks such as digging irrigation ditches, preparing soil for planting, or light clearing operations. Rice harvesters often employ these efficient engines for reliable operation during harvesting seasons.

Utility & Infrastructure Maintenance: Essential for repair and maintenance of underground utilities, cable installation, and small-scale roadwork. Their ability to maneuver in tight spots reduces manual labor and increases productivity.

Rental Fleets: Due to their versatility and ease of operation, these mini excavators are popular in equipment rental fleets, serving a wide range of short-term construction, homeowner, and landscaping projects.

Regular maintenance, including head gasket replacement with a quality kit like ours, is crucial to ensure these machines remain operational and efficient, minimizing downtime in critical projects.

Related & Similar Products

Beyond the full overhaul head gasket kit, a complete engine rebuild or repair often involves other critical components. We offer a wide range of related parts compatible with Yanmar 2TNE68 / Komatsu 2D68E engines and similar compact diesel engines, including:

Engine Rebuild Kits: Often include pistons, piston rings, cylinder liners/sleeves, main and connecting rod bearings.

Individual Gaskets & Seals: Such as oil pan gaskets, valve stem seals, crank seals for specific repairs.

Piston Assemblies: Pistons, piston rings, and piston pins.

Bearings: Main bearings, connecting rod bearings, and thrust washers.

Valvetrain Components: Intake and exhaust valves, valve guides, valve seats, valve springs.

Fuel System Parts: Fuel injectors, fuel pumps, fuel filters.

Cooling System Parts: Water pumps, thermostats, radiators, hoses.

Lubrication System Parts: Oil pumps, oil filters, oil coolers.

Electrical Components: Starters, alternators, glow plugs, wiring harnesses.

Engine Block & Cylinder Head Components: Cylinder heads, cylinder blocks (for major repairs).

These components are essential for comprehensive engine maintenance and can be found for various Yanmar (e.g., 3TNE68, 4TNE88) and Komatsu engine series, as well as for machinery from brands like Takeuchi, Daewoo, Kobelco, and New Holland.

Installation & Maintenance: Common Issues and Solutions

Common Head Gasket Issues:

Overheating: Often caused by inadequate cooling system bleeding after replacement, leading to air pockets and poor coolant circulation.

Oil and Coolant Mixing: Indicated by milky or frothy oil/coolant, suggesting an imperfect seal between oil and coolant passages.

Loss of Power/Misfires: Can result from compression loss due to an incorrectly installed, mismatched, or poorly torqued head gasket.

Coolant Leaks: Persistent external or internal leaks after replacement may point to improper surface preparation or undetected damage (e.g., warped cylinder head/block).

Excessive Exhaust Smoke (White): Indicates coolant entering the combustion chamber, possibly due to a faulty seal or cracks in the head/block.

Solutions & Maintenance Tips:

Thorough Surface Preparation: Before installing a new head gasket, ensure both the cylinder head and engine block surfaces are meticulously cleaned and perfectly flat. Even minor imperfections can lead to leaks. Professional machining might be necessary for warped surfaces.

Correct Torque Sequence & Specifications: Always follow the manufacturer's specified torque sequence and values for cylinder head bolts. Use a calibrated torque wrench and perform tightening in multiple stages as recommended.

Bleed Cooling System Properly: After refilling coolant, ensure all air is purged from the cooling system to prevent hot spots and overheating.

Regular Fluid Checks: Periodically check engine oil and coolant for signs of contamination (e.g., milky appearance). Monitor coolant levels and engine temperature closely.

Quality Parts: Always use high-quality, OEM-equivalent gasket kits to ensure durability and a proper seal.

Routine Maintenance: Adhere to regular maintenance schedules, including oil and filter changes (oil, fuel, air) and cooling system checks. Replace V-belts and check tension as recommended by the engine manual.

Professional Inspection: If persistent issues arise after an overhaul, seek professional diagnosis to identify underlying problems such as cracks in the engine block or cylinder head, or issues with other engine components (e.g., water pump, thermostat).

By following these guidelines, you can significantly extend the life and ensure the reliable operation of your Yanmar or Komatsu engine.