John Deere 4045 Engine Cylinder Head Gasket Repair Kit Construction Machinery Parts Repair

Support Alibaba online purchase

John Deere 4045 Engine Cylinder Head Gasket Repair Kit - Premium Construction Machinery Parts

Product Overview

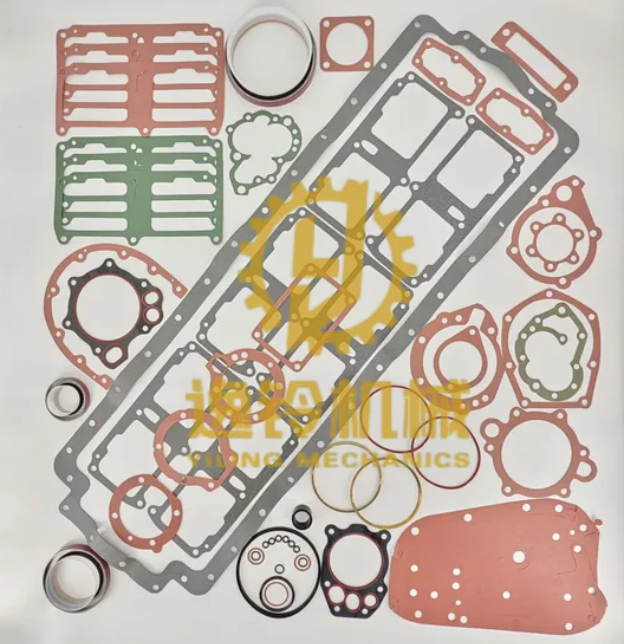

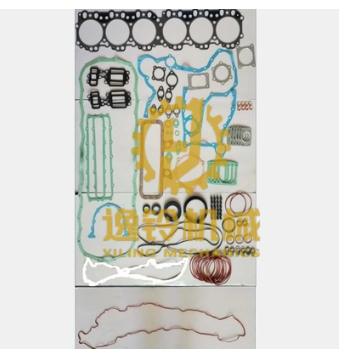

Ensure the longevity and optimal performance of your John Deere 4045 engine with our high-quality Cylinder Head Gasket Repair Kit. Designed specifically for construction machinery, this comprehensive kit provides all the necessary components for a reliable and lasting repair, preventing coolant leaks, oil contamination, and loss of compression. Our gaskets are manufactured to meet or exceed OEM specifications, guaranteeing a perfect fit and exceptional sealing capabilities under demanding operational conditions.

Product Specifications

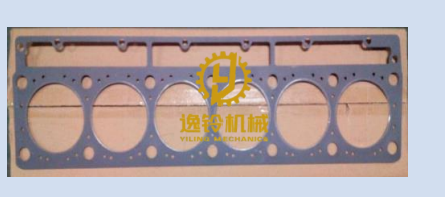

Part Name: Cylinder Head Gasket Repair Kit

Engine Model: John Deere 4045

Material: Multi-Layer Steel (MLS), Graphite, or Composite (depending on specific kit components)

Contents: Cylinder Head Gasket, Valve Cover Gasket, Intake Manifold Gasket, Exhaust Manifold Gasket, Valve Stem Seals, O-rings, and other essential seals and washers. (Specific contents may vary slightly by kit version)

Durability: Engineered for high temperature and pressure resistance, excellent sealing performance

Quality: Meets or exceeds OEM standards for fit, form, and function

Key Advantages and Selling Points

Superior Sealing Performance: Advanced materials ensure a tight, leak-free seal, preventing costly damage from fluid mixing or compression loss.

Extended Engine Life: Protects vital engine components from wear and tear caused by faulty gaskets, contributing to longer engine lifespan.

Cost-Effective Repair: A complete kit provides all necessary components for a comprehensive repair, saving time and money compared to sourcing individual parts.

OEM Quality and Fit: Manufactured to precise specifications for a perfect fit, ensuring straightforward installation and reliable operation.

Reduced Downtime: Quick and efficient repair helps minimize equipment downtime, maximizing productivity on the job site.

Applicable Equipment

This John Deere 4045 Engine Cylinder Head Gasket Repair Kit is primarily designed for various John Deere construction machinery and agricultural equipment utilizing the 4045 engine. This includes, but is not limited to:

John Deere Excavators (e.g., 160C LC, 180C LC)

John Deere Wheel Loaders (e.g., 544J, 624J)

John Deere Dozers (e.g., 650J, 700J)

John Deere Graders (e.g., 670D, 672D)

John Deere Agricultural Tractors (various models)

Other industrial applications powered by the John Deere 4045 engine.

Application Scenarios and Case Analysis

The John Deere 4045 engine is a workhorse in heavy-duty applications, and its reliable operation is critical for project success. A faulty cylinder head gasket can lead to significant operational issues. Here are common application scenarios and how our repair kit addresses them:

Construction Sites: Excavators and loaders with 4045 engines are constantly under immense stress, digging, lifting, and moving heavy materials. A leaking head gasket can lead to engine overheating, loss of power, and potential catastrophic failure. Our kit provides a robust solution to restore engine integrity, ensuring continuous operation for earthmoving, trenching, and material handling.

Case Study: A construction company experienced frequent overheating in their John Deere 160C LC excavator during a demanding urban infrastructure project. Diagnosis revealed a blown cylinder head gasket. After installing our repair kit, the engine temperature stabilized, power output was restored, and the excavator completed the project ahead of schedule, avoiding costly delays and further engine damage.Agricultural Operations: John Deere tractors equipped with the 4045 engine are vital for plowing, planting, and harvesting across vast farmlands. Engine issues during peak seasons can result in significant crop loss and financial setbacks. Our gasket kit ensures engines run efficiently, providing the necessary power for demanding agricultural tasks.

Case Study: A farmer noticed white smoke from the exhaust and coolant loss in his John Deere 6430 tractor during harvest. Investigation confirmed a damaged head gasket. Our repair kit was used, and the tractor quickly returned to full operation, allowing the farmer to complete the harvest without further interruption.Quarry and Mining Environments: Dozers and wheel loaders in these harsh environments face extreme dust, heat, and continuous heavy loads. A compromised head gasket can lead to severe engine degradation. Our durable gaskets withstand these conditions, maintaining engine performance for tasks like aggregate moving and overburden removal.

Case Study: In a large limestone quarry, a John Deere 700J dozer started showing signs of reduced power and oil in the coolant. The culprit was a failing cylinder head gasket. Implementing our repair kit allowed the dozer to regain its full operational capacity, ensuring consistent production rates in the challenging quarry environment.

Related Products

In addition to the John Deere 4045 Cylinder Head Gasket Repair Kit, we offer a wide range of related engine components and repair kits for various construction and agricultural machinery:

Cummins B/C Series Engine Gasket Kits: Suitable for excavators, loaders, and generator sets (e.g., Komatsu PC200, Hyundai R210, various power generation units).

Caterpillar C7/C9/C13 Engine Overhaul Kits: Used in large excavators, bulldozers, and trucks (e.g., Cat 320D, D6R, 777F).

Volvo D6/D8/D12 Engine Gasket Sets: Applicable to Volvo excavators, wheel loaders, and articulated haulers (e.g., EC210, L90, A25).

Perkins 1104/1106 Series Engine Component Kits: Found in many backhoe loaders, telehandlers, and industrial power units (e.g., JCB 3CX, Manitou MLT series).

Deutz BFM1013/BFM2012 Engine Repair Kits: Commonly used in road pavers, compactors, and industrial applications (e.g., Hamm rollers, Wirtgen pavers).

Common Installation and Maintenance Issues & Solutions

Proper installation and ongoing maintenance are crucial for the longevity of a cylinder head gasket. Here are common issues and their solutions:

Issue: Incorrect Torque Settings During Installation

Problem: Over-tightening can deform the gasket, while under-tightening can lead to insufficient sealing and premature failure.

Solution: Always follow the manufacturer's specified torque sequence and values for the cylinder head bolts. Use a calibrated torque wrench and perform tightening in stages.Issue: Contaminated Sealing Surfaces

Problem: Dirt, debris, or old gasket material on the cylinder head or engine block surfaces can prevent a proper seal, leading to leaks.

Solution: Thoroughly clean and inspect both the cylinder head and engine block surfaces before gasket installation. Ensure they are perfectly flat and free of any imperfections. Use a straightedge to check for warpage.Issue: Engine Overheating

Problem: Persistent overheating can degrade gasket materials, leading to failure. This can be caused by coolant leaks, radiator issues, or thermostat malfunctions.

Solution: Address the root cause of overheating promptly. Regularly check coolant levels, inspect the cooling system for leaks, and ensure the radiator and fan are functioning correctly. Consider flushing the cooling system during gasket replacement.Issue: Using Inferior Quality Gaskets

Problem: Cheap, non-OEM quality gaskets may not withstand the high temperatures and pressures of the engine, leading to early failure.

Solution: Always invest in high-quality, OEM-spec or equivalent aftermarket gaskets, like the one offered here, to ensure durability and reliability.