John Deere Full Gasket Set, without crank seals, RE506220

Support Alibaba online purchase

John Deere Full Gasket Set, without Crank Seals, RE506220

Product Overview

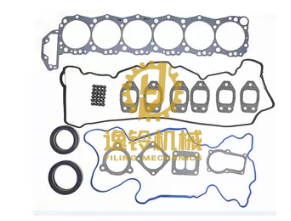

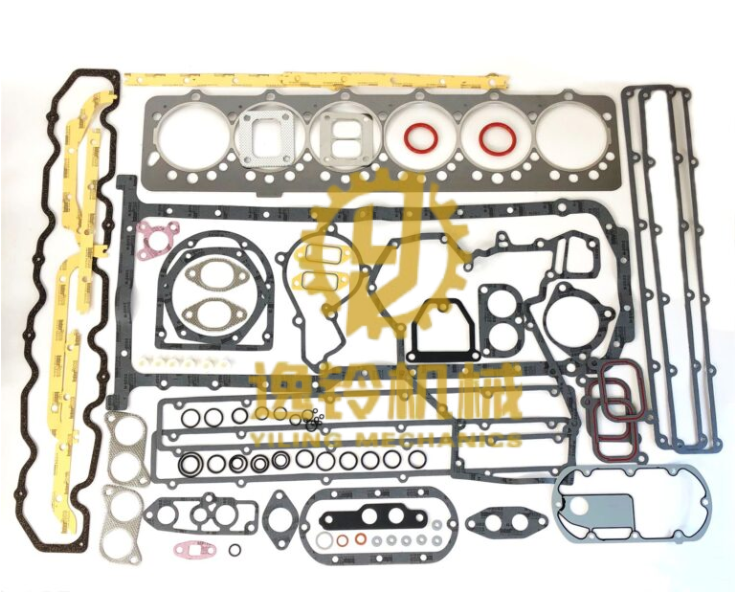

The John Deere Full Gasket Set, RE506220, is a high-quality, comprehensive solution designed to ensure a perfect seal for your John Deere engine. This set provides all the necessary gaskets (excluding crank seals) to facilitate a complete engine overhaul or major repair, preventing leaks and maintaining optimal engine performance. Manufactured to meet or exceed OEM specifications, our gasket set guarantees durability and reliability, offering peace of mind for demanding agricultural and construction applications.

Product Specifications & Advantages

Part Number: RE506220

Type: Full Gasket Set (without crank seals)

Material: High-grade, durable materials resistant to extreme temperatures and pressures.

Precision Fit: Engineered for a perfect fit, ensuring no leaks and optimal engine sealing.

Enhanced Engine Performance: Helps maintain proper compression and oil pressure, contributing to better fuel efficiency and power output.

Longevity: Designed for extended service life, reducing the need for frequent replacements.

Cost-Effective: A comprehensive solution that saves time and money compared to purchasing individual gaskets.

Applicable Equipment:

This gasket set is specifically designed for various John Deere engine models. It is commonly used in, but not limited to, the following John Deere equipment:

John Deere Agricultural Tractors (e.g., 6000, 7000, 8000 Series)

John Deere Combine Harvesters

John Deere Construction Equipment (e.g., Excavators, Wheel Loaders)

John Deere Industrial Engines

Application Scenarios & Case Studies

The John Deere Full Gasket Set RE506220 is essential for maintaining the integrity and performance of heavy-duty John Deere machinery across various demanding applications.

Application Scenarios:

Agricultural Operations: Crucial for ensuring the reliability of tractors and combines during critical farming seasons, preventing costly downtime during planting, cultivation, and harvesting.

Construction Sites: Vital for excavators, loaders, and other heavy equipment where continuous operation and high power output are required. A well-sealed engine means consistent performance and reduced risk of environmental damage from leaks.

Industrial Power Generation: For John Deere industrial engines used in generators or pumps, reliable gaskets ensure efficient and leak-free operation, critical for consistent power supply.

Case Study: Farm in Iowa

A large agricultural farm in Iowa experienced persistent oil leaks from one of their John Deere 8R series tractors, impacting its efficiency during the corn harvest. After diagnosis, it was determined that several engine gaskets were compromised. Replacing them with the John Deere Full Gasket Set RE506220 resolved the leaks completely. The tractor regained its optimal performance, significantly reducing oil consumption and preventing further environmental contamination. This repair allowed the farm to complete their harvest on schedule, avoiding substantial losses.

Related Products

To complement your maintenance and repair needs, we also offer a range of other essential John Deere engine components:

John Deere Crank Seals (Front & Rear): Essential for completely sealing the crankshaft, preventing oil leaks at the front and rear of the engine. Applicable to all John Deere engines requiring RE506220.

John Deere Cylinder Head Gaskets: Specifically designed for sealing the cylinder head to the engine block, critical for maintaining compression and preventing coolant/oil mixing. Applicable to John Deere 6000, 7000, 8000 series tractors, and compatible combine models.

John Deere Oil Pan Gaskets: Ensures a tight seal for the oil pan, preventing leaks from the bottom of the engine. Applicable to various John Deere agricultural and construction equipment.

John Deere Valve Cover Gaskets: Seals the valve cover to the cylinder head, preventing oil leaks from the top of the engine. Compatible with a wide range of John Deere engines, including those in tractors, excavators, and industrial applications.

Common Installation & Maintenance Issues and Solutions

Proper installation and regular maintenance are crucial for the longevity and performance of your John Deere engine and its gasket set. Here are some common issues and their solutions:

Issue: Gasket Leaks After Installation

Cause: Incorrect torque specifications, damaged mating surfaces, or improper gasket alignment.

Solution: Always follow the manufacturer's torque specifications (refer to your John Deere service manual). Ensure all mating surfaces are thoroughly cleaned and free of debris, old gasket material, or scratches. Use a surface preparation tool if necessary. Carefully align the gaskets before tightening bolts.Issue: Premature Gasket Failure

Cause: Over-tightening leading to crushing, under-tightening causing insufficient compression, or extreme operating temperatures.

Solution: Use a calibrated torque wrench for all fasteners. Monitor engine temperature to prevent overheating, which can degrade gasket material. Ensure proper cooling system function.Issue: Contamination of Fluids (Oil/Coolant Mixing)

Cause: Head gasket failure, often due to overheating or improper installation.

Solution: Immediately address any signs of overheating. If contamination is detected, replace the head gasket following precise installation procedures, including checking for cylinder head warpage.Issue: Gasket Deterioration Over Time

Cause: Natural wear and tear, exposure to harsh chemicals or extreme conditions.

Solution: Adhere to recommended service intervals for gasket inspection and replacement. Use only high-quality, OEM-spec or equivalent gaskets like RE506220 for maximum durability.