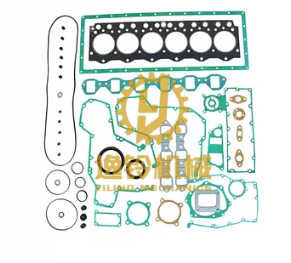

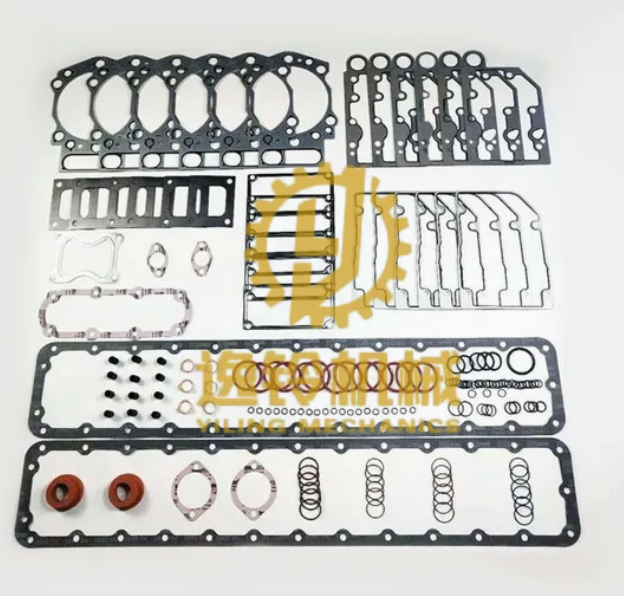

Engine Gasket Kit OEM6212-K1-9901 for Komatsu 6D140, Auto Spare Part Made in China

Support Alibaba online purchase

Premium Engine Gasket Kit OEM6212-K1-9901 for Komatsu 6D140 – Your Reliable Auto Spare Part from China

Ensure the longevity and optimal performance of your heavy machinery with our high-quality **Engine Gasket Kit OEM6212-K1-9901**. Specifically engineered for the **Komatsu 6D140 engine**, this auto spare part, proudly manufactured in China, offers a perfect fit and exceptional sealing capabilities. It's the ideal solution for maintaining engine integrity and preventing costly leaks, ensuring your equipment runs smoothly and efficiently.

Product Specifications

OEM Part Number: 6212-K1-9901

Material: High-grade composite materials, rubber, and metal components

Compatibility: Specifically designed for Komatsu 6D140 engine

Manufacturing Origin: China

Kit Contents: Comprehensive set including cylinder head gaskets, manifold gaskets, valve cover gaskets, oil pan gaskets, and various seals (exact contents may vary slightly based on specific engine requirements).

Key Advantages & Applications

Superior Sealing Performance: Crafted from durable, heat-resistant materials, our gasket kit provides an excellent seal, preventing oil leaks, coolant leaks, and compression loss. This ensures maximum engine efficiency and reduces the risk of engine damage.

Extended Engine Life: By maintaining proper sealing, the kit protects internal engine components from contaminants and ensures optimal operating conditions, significantly prolonging the lifespan of your Komatsu 6D140 engine.

Cost-Effective Solution: As a high-quality aftermarket part, it offers a reliable and affordable alternative to OEM replacements without compromising on performance or durability.

Precise Fit: Manufactured to strict OEM specifications, this gasket kit guarantees a perfect fit, simplifying installation and reducing downtime.

This **Engine Gasket Kit** is essential for any equipment powered by the **Komatsu 6D140 engine**. This includes a wide range of heavy machinery commonly used in various demanding industries:

Excavators: Komatsu PC400, PC450, PC490 series, used for digging, trenching, and demolition in construction and mining.

Wheel Loaders: Komatsu WA470, WA480 series, vital for loading aggregate, earth, and other materials in construction, quarrying, and material handling.

Bulldozers: Komatsu D85, D155 series, critical for pushing earth, grading, and clearing land in civil engineering and large-scale agricultural projects.

Articulated Dump Trucks: Komatsu HM300, HM400 series, used for transporting large volumes of material in mining and construction sites.

Application Scenarios & Case Study

Our Engine Gasket Kit OEM6212-K1-9901 is crucial for maintaining the operational integrity of heavy machinery in challenging environments. Here are typical application scenarios and a relevant case analysis:

Construction Sites: In large-scale infrastructure projects, such as highway construction or commercial building developments, Komatsu excavators and loaders operate continuously under heavy loads. A worn-out gasket can lead to coolant leaks and engine overheating, causing significant downtime. Our gasket kit provides a reliable seal, preventing such failures and ensuring continuous operation, thereby meeting project deadlines.

Mining Operations: Mining machinery, including Komatsu rigid dump trucks and bulldozers, works in extreme conditions with constant vibration and temperature fluctuations. Gaskets are vital for sealing critical engine components against dust and debris. Regular replacement with our durable gasket kit minimizes the risk of contamination-induced engine wear, reducing maintenance costs and improving operational safety.

Quarrying: Wheel loaders in quarries handle abrasive materials like crushed rock and sand. The constant strain demands robust engine components. A failing gasket can lead to power loss and increased fuel consumption. Installing our precision-engineered gasket kit restores engine efficiency, optimizing fuel economy and maximizing material handling capacity.

**Case Analysis:** A major construction company operating in a harsh desert environment faced frequent engine overheating issues with their Komatsu PC400 excavators. Investigations revealed deteriorated cylinder head gaskets due to extreme heat and prolonged use. After replacing the faulty gaskets with our OEM6212-K1-9901 kit, the company reported a significant reduction in overheating incidents, improved engine performance, and extended service intervals. This resulted in substantial savings on repair costs and increased equipment availability, directly contributing to project profitability.

---Related Products & Applications

Beyond our premium gasket kit, we also offer a comprehensive range of Komatsu engine components designed to keep your machinery in top condition:

Cylinder Liners: Essential for maintaining optimal engine compression and heat transfer. Suitable for various Komatsu engine models, including 6D125, S6D140, and SA6D170, found in excavators, bulldozers, and generators.

Piston Rings: Critical for sealing the combustion chamber and regulating oil consumption. Compatible with Komatsu 6D105, 6D110, and SAA6D125 engines, widely used in loaders and dump trucks.

Main Bearings & Con Rod Bearings: Support the crankshaft and connecting rods, ensuring smooth engine rotation. Applicable to a broad spectrum of Komatsu engines, such as the 6D95, 6D102, and SAA6D140, powering a variety of construction and mining equipment.

Engine Valves (Intake & Exhaust): Regulate the flow of air and exhaust gases, vital for engine breathing. Available for Komatsu 4D95, 6D107, and SAA6D170 engines, commonly found in smaller excavators and forklifts.

Oil Pumps & Water Pumps: Crucial for engine lubrication and cooling systems. Compatible with most Komatsu engine series, ensuring proper fluid circulation in all heavy-duty applications.

Installation & Maintenance Tips

Proper installation and regular maintenance are key to maximizing the lifespan and performance of your engine gaskets. Here are common issues and their solutions:

Problem: Improper Surface Preparation

**Issue:** Residual old gasket material, dirt, or uneven surfaces can prevent a new gasket from seating properly, leading to leaks.

**Solution:** Always thoroughly clean and inspect mating surfaces. Use a non-abrasive scraper to remove old gasket material and a degreaser to ensure surfaces are free of oil and debris. Check for warpage or damage to the engine components before installation.Problem: Overtightening or Undertightening Bolts

**Issue:** Overtightening can crush the gasket, causing it to fail prematurely. Undertightening results in insufficient compression, leading to leaks.

**Solution:** Always follow the manufacturer's torque specifications for all bolts. Use a calibrated torque wrench and tighten bolts in the correct sequence (e.g., spiral or cross-pattern) to ensure even pressure distribution across the gasket.Problem: Using the Wrong Gasket Type or Material

**Issue:** Installing a gasket not designed for the specific application or operating conditions will lead to quick failure.

**Solution:** Ensure you are using the correct OEM part number or a direct equivalent. Our OEM6212-K1-9901 is specifically for Komatsu 6D140. Verify the gasket material is suitable for the operating temperatures, pressures, and fluids it will encounter.Problem: Neglecting Coolant or Oil Leaks

**Issue:** Small leaks, if ignored, can escalate into major problems, causing engine damage from overheating or insufficient lubrication.

**Solution:** Regularly inspect your engine for any signs of leaks. Address even minor leaks promptly. This includes routine checks of fluid levels and visual inspection of gasket areas. Early detection and replacement of failing gaskets can prevent catastrophic engine failures.