6212-K2-9901 Diesel Engine SA6d140 Parts Overhaul Full Gasket Kit 6212-K1-9901 6D140 Upper and Lower Gasket Set

Support Alibaba online purchase

Premium Overhaul Full Gasket Kit for SA6D140 Diesel Engines (6212-K2-9901 / 6212-K1-9901)

Ensure the longevity and optimal performance of your Komatsu SA6D140 diesel engine with our comprehensive Overhaul Full Gasket Kit. Specifically designed to meet or exceed OEM specifications, this kit provides all the necessary gaskets and seals for a complete engine overhaul, ensuring a reliable and leak-free rebuild.

Product Parameters:

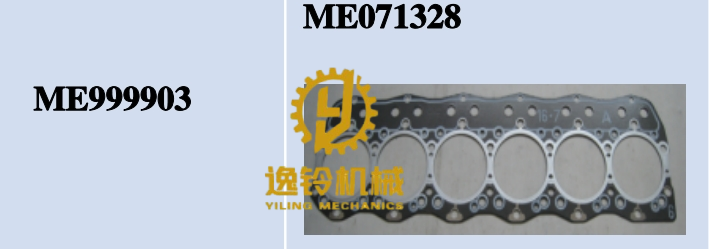

Part Numbers: 6212-K2-9901 (Full Gasket Kit), 6212-K1-9901 (Upper and Lower Gasket Set)

Engine Model Compatibility: Komatsu SA6D140, 6D140 Diesel Engines

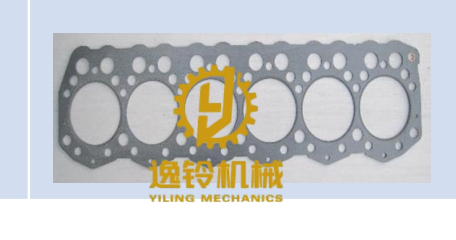

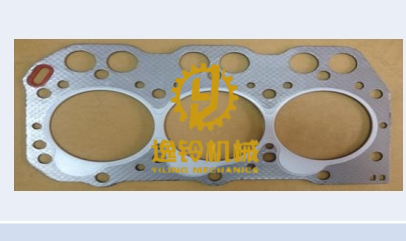

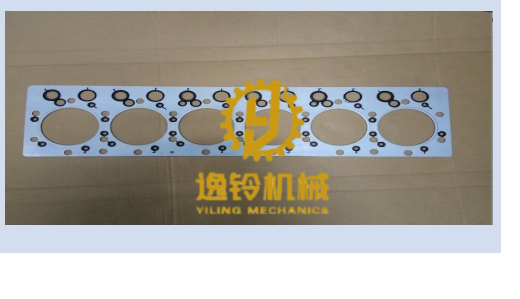

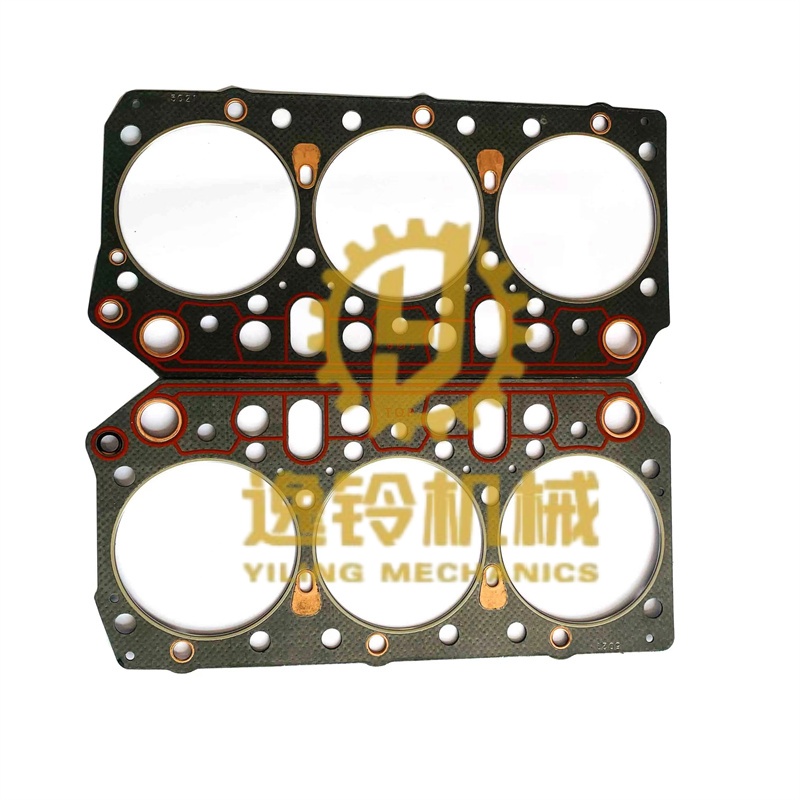

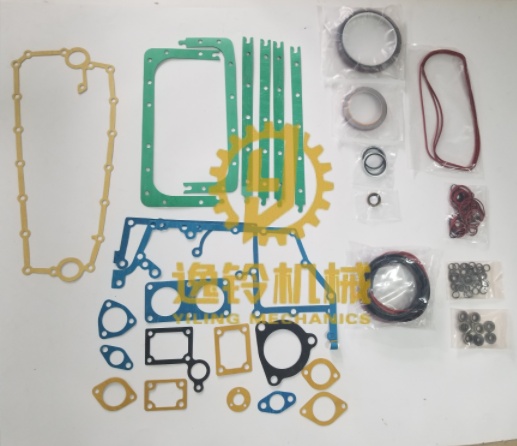

Kit Contents: Includes all necessary gaskets and seals for a full engine overhaul (e.g., cylinder head gasket, valve cover gasket, oil pan gasket, intake/exhaust manifold gaskets, various O-rings and seals).

Material: High-quality, durable materials engineered for heat resistance and sealing integrity.

Packaging: Securely packaged to prevent damage during transit.

Key Product Advantages and Selling Points:

Superior Quality: Manufactured with precision to meet stringent quality standards, ensuring a perfect fit and long-lasting performance.

Complete Overhaul Solution: This full gasket kit eliminates the need to source individual gaskets, saving time and ensuring you have every component required for a thorough engine rebuild.

Enhanced Engine Reliability: By replacing worn or deteriorated gaskets, this kit helps prevent oil leaks, coolant leaks, and compression loss, extending the lifespan of your engine.

Cost-Effective: A complete kit often offers better value than purchasing individual parts, reducing overall repair costs.

OEM Equivalent or Better: Designed to provide performance equal to or superior to original equipment manufacturer parts.

Applicable Equipment:

This SA6D140 Diesel Engine Overhaul Full Gasket Kit is primarily designed for various Komatsu heavy-duty equipment powered by the SA6D140 or 6D140 engine, including but not limited to:

Komatsu Excavators: PC600, PC650, PC750 series and other models utilizing the SA6D140 engine.

Komatsu Wheel Loaders: WA600, WA700 series and similar models.

Komatsu Dozers: D155AX, D275A series and other compatible bulldozers.

Komatsu Dump Trucks: HM400, HM500 series and other articulated dump trucks.

Other Komatsu Heavy Machinery: Including generators, industrial power units, and marine applications using the SA6D140 engine.

Application Scenarios and Case Studies:

The Komatsu SA6D140 engine is a workhorse in demanding environments, and our gasket kit is essential for its continued operation in various critical applications:

Mining Operations: Large excavators and dump trucks powered by the SA6D140 are fundamental to extracting minerals. A reliable engine overhaul with our gasket kit ensures minimal downtime in these high-production environments. For instance, a major open-pit mine in Australia successfully extended the service life of their PC750 excavators by performing routine engine overhauls using our full gasket kits, significantly reducing operational costs.

Construction Projects: Dozers and wheel loaders are vital for earthmoving and material handling on large construction sites. Preventing oil and coolant leaks through a proper overhaul enhances safety and efficiency. A recent highway construction project in the United States utilized our kits for their D155AX dozers, leading to improved fuel efficiency and reduced environmental impact from leaks.

Quarrying and Aggregate Production: Equipment like large wheel loaders continuously move aggregates. The robustness of the SA6D140 engine is critical here. Our gasket kits ensure these engines withstand the constant vibration and dust, maintaining optimal performance. A quarry in Canada reported a 15% increase in operational uptime after switching to our full gasket kits for their WA600 loaders.

Heavy Demolition: Excavators fitted with the SA6D140 engine are frequently used in demolition. The stresses on the engine are immense. Our high-quality gaskets contribute to the engine's ability to handle these extreme pressures without failure.

Related and Similar Products:

Beyond this comprehensive gasket kit, we also offer a range of related and similar products to support your Komatsu SA6D140 engine maintenance and other heavy equipment needs:

Individual SA6D140 Gaskets & Seals: For targeted repairs, we stock individual cylinder head gaskets, valve stem seals, oil pan gaskets, etc. Applicable to specific leak repairs on Komatsu SA6D140 engines.

Engine Bearing Kits: Main bearings, connecting rod bearings, and thrust washers for SA6D140 engine crankshaft overhauls. Applicable to any Komatsu equipment requiring bearing replacement.

Engine Overhaul Kits (Partial): May include pistons, liners, rings, and select gaskets for more targeted engine rebuilds. Applicable to SA6D140 engines experiencing specific wear issues.

Fuel System Components: Fuel injectors, fuel pumps, and filters for Komatsu SA6D140 engines. Applicable to any Komatsu machinery needing fuel system repair or maintenance.

Turbochargers: Replacement turbochargers for SA6D140 engines to restore power and efficiency. Applicable to Komatsu excavators, loaders, dozers experiencing turbocharger issues.

Cooling System Components: Water pumps, thermostats, and radiators for SA6D140 engines. Applicable to all Komatsu equipment requiring cooling system repairs.

Common Installation & Maintenance Issues and Solutions:

Proper installation and routine maintenance are crucial for maximizing the lifespan of your SA6D140 engine and the effectiveness of our gasket kit. Here are some common issues and their solutions:

Issue: Gasket Leaks after Installation.

Solution: Often caused by improper torque sequence or insufficient surface preparation. Ensure all mating surfaces are thoroughly cleaned, free of old gasket material and debris. Follow the manufacturer's specified torque sequence and values precisely. Avoid over-tightening, which can crush gaskets, or under-tightening, which can lead to insufficient sealing.Issue: Premature Gasket Failure.

Solution: Can be due to engine overheating, incorrect gasket material for the application, or improper installation. Verify the engine cooling system is functioning correctly. Always use gaskets specifically designed for the SA6D140 engine. Re-check torque settings after initial engine run-in.Issue: Difficulty Seating Gaskets.

Solution: Some gaskets, especially those for cylinder heads, require careful alignment. Use alignment pins or bolts to properly position the gasket before lowering the component. Ensure the gasket is not pinched or folded during installation.Issue: Contamination of New Gaskets.

Solution: Handle new gaskets with clean hands and avoid contact with oil, grease, or dirt before installation, unless specified by the gasket manufacturer (e.g., for certain rubber seals requiring lubrication). Contaminants can compromise the sealing integrity.Maintenance Tip: Regular Fluid Checks.

Solution: Regularly inspect engine oil, coolant, and hydraulic fluid levels. Any sudden drops could indicate a potential gasket failure. Address leaks promptly to prevent further engine damage.Maintenance Tip: Visual Inspection.

Solution: Periodically inspect the exterior of the engine for any signs of leaks, especially around common gasket areas like the oil pan, valve cover, and cylinder head. Early detection can prevent minor issues from becoming major repairs.