Me031521 Fit for Mitsubishi 6D14 6D14t Cylinder Head Gasket

Support Alibaba online purchase

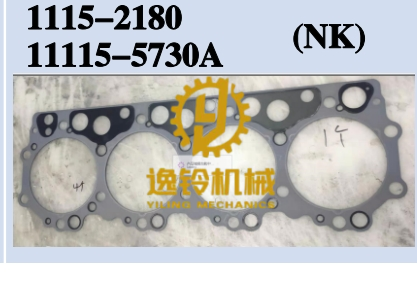

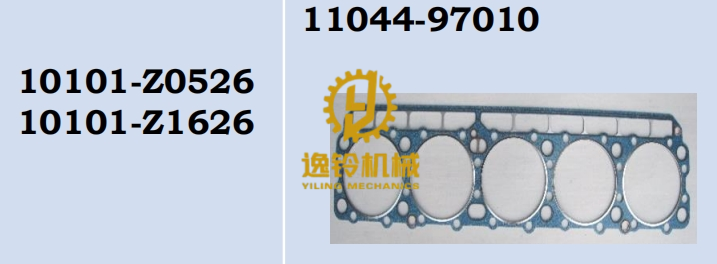

ME031521 Cylinder Head Gasket for Mitsubishi 6D14 / 6D14T Engines

Product Overview

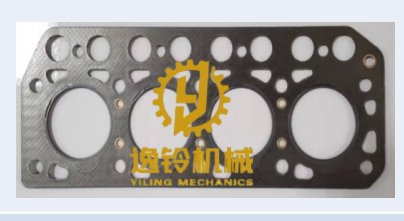

The ME031521 Cylinder Head Gasket is a high-quality replacement part specifically engineered for Mitsubishi 6D14 and 6D14T diesel engines. This critical component provides the essential seal between the engine block and the cylinder head, preventing the leakage of combustion gases, coolant, and engine oil. A properly functioning cylinder head gasket is vital for maintaining correct engine compression, preventing overheating, and ensuring overall engine longevity and performance.

Product Specifications

Part Number: ME031521

Engine Model Compatibility: Mitsubishi 6D14, Mitsubishi 6D14T

Type: Cylinder Head Gasket

Material: High-quality composite or Multi-Layer Steel (MLS) construction for durability and optimal sealing (Specify material based on specific product type if known, otherwise use a general description)

Function: Seals combustion chambers, coolant passages, and oil passages.

Design: Precision engineered to meet or exceed OEM specifications for perfect fit and reliable performance.

Key Advantages & Selling Points

Precise Fit: Engineered specifically for Mitsubishi 6D14 and 6D14T engines, ensuring perfect alignment and installation.

Superior Sealing: Constructed from robust materials designed to withstand the extreme pressures and temperatures of diesel combustion.

Durability: Resists breakdown from heat, oil, and coolant, providing long-lasting performance.

Prevents Leaks: Effectively prevents inter-cylinder leakage, coolant/oil mixing, and external leaks.

Restores Performance: Crucial for restoring proper engine compression and preventing issues caused by gasket failure.

Reliable Replacement: A trusted component for engine repair and overhaul, restoring engine integrity.

Compatible Equipment

This ME031521 cylinder head gasket is compatible with a range of heavy-duty equipment powered by the reliable Mitsubishi 6D14 and 6D14T engines. These engines were widely used in:

Mitsubishi Fuso Trucks: Various models, commonly in the FK and FM series.

Construction Machinery: Including certain models of excavators, loaders, and cranes from manufacturers that utilized Mitsubishi engines (e.g., older Caterpillar models with Mitsubishi power, Komatsu, Kobelco).

Industrial Equipment: Such as generators, pumps, and other static or mobile industrial applications.

Buses: Certain bus chassis equipped with the 6D14/6D14T engines.

Application Scenarios & Case Studies

The equipment powered by Mitsubishi 6D14/6D14T engines operates in demanding environments where engine reliability is paramount. The cylinder head gasket plays a critical role in these scenarios:

Scenario: Construction Sites & Mining Operations

Equipment like excavators and loaders face heavy loads, continuous operation, and exposure to dust and variable temperatures. A failing head gasket can lead to engine overheating and loss of power, causing critical downtime.

Case Analysis: A construction company's excavator with a 6D14T engine experienced coolant loss and reduced performance. Diagnosis showed head gasket failure due to prolonged heavy use and heat exposure. Replacing the gasket with a high-quality ME031521 restored full engine function and prevented further damage, highlighting the need for durable components in harsh work environments.Scenario: Long-Haul Transportation

Mitsubishi Fuso trucks often operate on long routes, requiring engines that can sustain high power output for extended periods. Gasket integrity is crucial for preventing breakdowns far from service centers.

Case Analysis: A transport fleet proactively replaced cylinder head gaskets using ME031521 during scheduled engine overhauls on their 6D14 trucks. This preventive maintenance strategy significantly reduced unexpected roadside breakdowns caused by gasket failures, improving fleet efficiency and reliability.Scenario: Power Generation & Industrial Use

6D14/6D14T engines are used in generators and industrial pumps where consistent, reliable power is non-negotiable. Gasket failure here can mean critical system downtime.

Case Analysis: An industrial plant relying on a 6D14-powered generator experienced erratic voltage output and signs of internal engine issues. Investigation traced the problem to a combustion leak through the head gasket. Replacing the gasket with a reliable part resolved the combustion issue, stabilizing generator performance and ensuring consistent power supply.

Related & Similar Products

When replacing a cylinder head gasket, or servicing a Mitsubishi 6D14/6D14T engine, other related parts are often needed or recommended. We also offer components for similar engines:

Engine Overhaul Gasket Sets: Comprehensive sets including all necessary gaskets, seals, and O-rings for a complete engine rebuild on 6D14/6D14T engines.

Cylinder Head Bolts: Often need replacement as they are "stretch-to-yield" bolts designed for single use. Essential for proper clamping force.

Intake & Exhaust Manifold Gaskets: Typically replaced when the cylinder head is removed.

Valve Cover Gaskets: Needed when accessing valve train components during head removal/installation.

Piston & Liner Kits: For more extensive engine wear, often replaced during a major overhaul.

Engine Bearings: Connecting rod and main bearings, critical for crankshaft rotation.

Water Pump & Oil Pump: Vital components for engine cooling and lubrication, often serviced or replaced during major engine work.

Gaskets & Parts for Similar Mitsubishi Engines: Such as parts for 6D15, 6D16, and other related Mitsubishi heavy-duty diesel engines used in similar equipment.

Common Installation & Maintenance Issues and Solutions

Replacing a cylinder head gasket requires precision. Here are common issues and how to address them:

Issue: Improper Surface Preparation.

If the cylinder head or engine block surface is not perfectly clean and flat, the new gasket will not seal correctly, leading to premature failure.

Solution: Thoroughly clean both the head and block surfaces using appropriate tools (e.g., plastic scrapers, chemical removers - avoid abrasive pads). Check surfaces for warpage using a straight edge and feeler gauge. Machine shop service may be required if surfaces are warped or damaged.Issue: Incorrect Head Bolt Torque or Sequence.

Over-tightening, under-tightening, or not following the specific multi-stage torque sequence can unevenly load the gasket, causing leaks.

Solution: Always use a calibrated torque wrench. Follow the engine manufacturer's specified torque values and tightening sequence *exactly*. Most engines require multiple torque stages and specific patterns (e.g., center outward).Issue: Reusing Old Head Bolts.

Many modern engines use "torque-to-yield" (TTY) or "stretch" bolts that are designed to be used only once. Reusing them results in insufficient clamping force and potential failure.

Solution: Always replace head bolts with new ones whenever the cylinder head is removed.Issue: Underlying Cause of Failure Not Addressed.

Gasket failure is often a symptom (e.g., from chronic overheating, detonation, or coolant system issues) rather than the primary problem.

Solution: Diagnose the root cause of the original gasket failure. Check the cooling system (radiator, thermostat, water pump, hoses), fuel injection timing, and look for signs of detonation or pre-ignition before installing the new gasket.